Fissuration par corrosion sous contrainte dans l'acier inoxydable peut entraîner des défaillances soudaines et inattendues. Tuyauterie en acier inoxydable et raccords sont utilisés dans un large éventail d'applications, leur fiabilité est donc essentielle. Une compréhension approfondie de la fissuration par corrosion sous contrainte et la réduction de la probabilité de son apparition garantissent le bon fonctionnement des systèmes de tuyauterie.

Qu'est-ce que la corrosion sous contrainte dans l'acier inoxydable ? Une menace silencieuse !

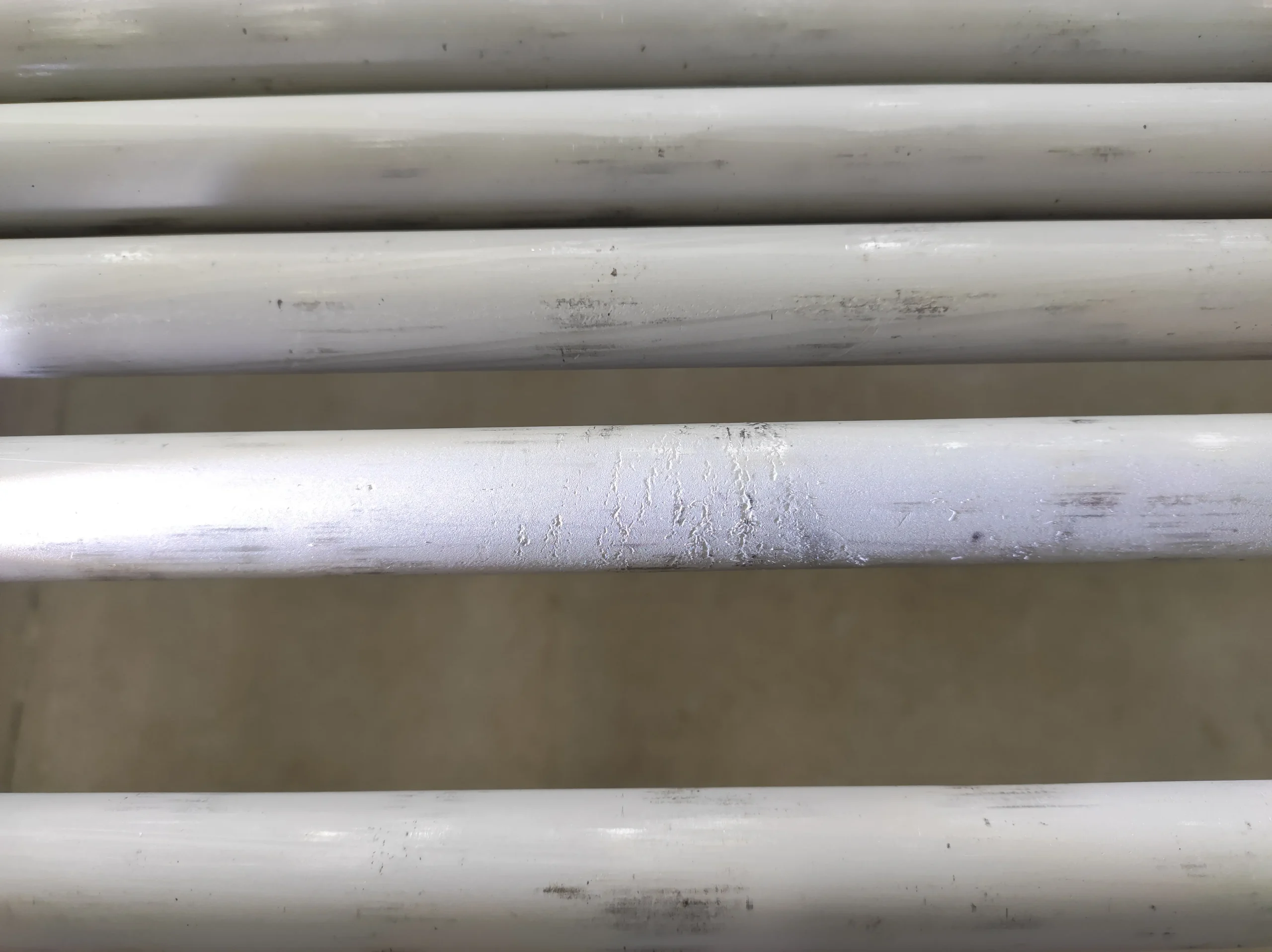

La corrosion sous contrainte de l'acier inoxydable est une forme grave de corrosion. Elle se produit lorsqu'une contrainte de traction, une environnement corrosif et un matériau sensible se combinent. Des fissures se créent, s'étendent et se propagent dans le métal. Lorsque la fissuration par corrosion sous tension se produit, corrosion sévère ne se produit généralement pas.

Facteurs clés à l'origine de la corrosion sous contrainte dans l'acier inoxydable

D'une part, les contraintes appliquées générées pendant le fonctionnement. D'autre part, les contraintes résiduelles générées lors de la fabrication. Soudage produit d'importantes contraintes résiduelles. Une pression interne élevée dans la canalisation peut également être un facteur contributif.

Environnements corrosifs peuvent également entraîner une CSC, notamment les chlorures, les températures élevées, les produits caustiques, etc.

Aciers inoxydables austénitiques (par exemple 304, 316) sont plus sensibles. Les matériaux ferritiques ou aciers inoxydables duplex sont plus résistants.

Les températures élevées accélèrent considérablement l'apparition de la CSC. Le risque augmente généralement à des températures supérieures à 60 °C (140 °F). Les solutions de chlorure chaudes sont particulièrement dangereuses.

Les fissures peuvent se développer et s'agrandir lentement. Mais elles peuvent s'étendre soudainement et sans avertissement. Plus la durée d'exposition est longue, plus le risque est grand.

Environnements propices à la formation de CSC pour l'acier inoxydable

| Type d'environnement | Exemples courants | Grades d'acier inoxydable sensibles |

|---|---|---|

| Solutions pour les chlorures | Eau de mer, tours de refroidissement, saumures | austénitique (304, 316) |

| Solutions caustiques | Environnements à pH élevé, alcalis forts | Austénitique (304, 316) |

| Eau à haute température | Chaudières, chauffe-eau | Austénitique (304, 316) |

| Gaz acide (H2S) | Production de pétrole et de gaz | Toutes les qualités d'acier inoxydable (moins courantes pour les duplex) |

| Condensats acides | Désulfuration des gaz de combustion (DGC) | Austénitique, certains duplex |

Ce que nous faisons

Stratégies de prévention de la corrosion sous contrainte dans l'acier inoxydable

| Stratégie | Action | Avantage pour les tuyaux/raccords |

|---|---|---|

| Sélection des matériaux | Utiliser des grades résistants (Duplex, Super Duplex) | Meilleure résistance à la CSC |

| Réduction du stress | Traitement post-soudure , traitement thermiquegrenaillage de précontrainte | Réduit les contraintes résiduelles |

| Contrôle de l'environnement | Réduire les chlorures, abaisser la température, ajouter des inhibiteurs | Limite le potentiel corrosif |

| Optimisation de la conception | Éviter les crevasses et les angles vifs | Empêche la concentration des contraintes |

| Finition de la surface | Surfaces lisses et polies | Réduit les sites d'initiation des fissures |

| Soudage correct | Contrôler l'apport de chaleur, utiliser des produits de remplissage à faible teneur en carbone | Minimise sensibilisation, le stress |

Impact de la CSC sur les tubes et raccords en acier inoxydable

La fissuration par corrosion sous tension se traduit généralement par une fracture fragile soudaine qui se produit sans avertissement. Cela peut entraîner une défaillance complète du système.

Les fuites de fluides dangereux sont extrêmement dangereuses, car elles peuvent blesser le personnel et endommager l'environnement.

Les défaillances peuvent entraîner des temps d'arrêt immédiats et des pertes de production importantes. Les réparations sont coûteuses.

Les fissures de CSC sont souvent subtiles et difficiles à détecter à l'œil nu, ce qui nécessite souvent des essais non destructifs.

Il se peut qu'une section entière de la conduite doive être remplacée. Cela est dû à des dommages localisés qui ne peuvent pas être réparés.

Choix de l'acier inoxydable pour la résistance à la corrosion par frottement

- Aciers inoxydables duplex (par exemple 2205, 2507) : ils présentent une excellente résistance à la fissuration par corrosion sous tension. Leur microstructure hybride ferrite-austenite y contribue, ce qui les rend idéales pour une utilisation dans des environnements riches en chlorures.

- Alliages à haute teneur en nickel (par exemple Alliage 800et Hastelloy) : Ces alliages présentent une excellente résistance à la fissuration par corrosion sous tension. Ils conviennent à des applications extrêmement environnements corrosifs et peuvent résister à des températures élevées et à de fortes concentrations de produits corrosifs.

- Alliages à faible teneur en carbone (par ex. 304L, 316L) : Bien qu'ils ne soient pas immunisés, leur faible teneur en carbone les aide. Elle réduit la sensibilisation pour améliorer la résistance aux corrosion intergranulaire.

- Une fabrication correcte : Même les qualités résistantes nécessitent un traitement approprié. Éviter un travail à froid excessif. Contrôler les paramètres de soudage.

Approvisionnement en composants fiables

Choisir un un fabricant qui a une grande expérience de l'acier inoxydable et qui comprend ses propriétés uniques. Cela permet d'obtenir des résultats de moulage optimaux.

Recherchez des capacités d'outillage de pointe. L'outillage de précision est essentiel et peut affecter la qualité et l'uniformité des pièces.

Veiller à la rigueur qualité les contrôles sont en place, y compris les contrôles dimensionnels, etc. Vérification de l'intégrité des matériaux et rapports d'essais de matériaux sont également essentiels.

Travailler avec des fabricants réputés qui offrent des produits en acier inoxydable fiables et ont certifications(par exemple ISO 9001 et CE-PED).

Confirmez que le fabricant peut répondre à vos exigences en matière de volume de production. Il doit être en mesure de réaliser des prototypes et de produire des volumes importants.

Vous voudrez peut-être aussi lire :

Impact of Internal Pipe Corrosion

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/