Qu'est-ce que le carbure dans l'acier inoxydable ? ? Tuyaux en acier inoxydable et raccords sont largement utilisés, mais ils présentent des faiblesses. Les carbures se forment dans des conditions spécifiques et peuvent sérieusement affecter les performances. Ils peuvent entraîner l'effondrement de votre système de tuyauterie.

Qu'est-ce que le carbure dans l'acier inoxydable ? Composés microscopiques !

Les carbures sont des composés formés lorsque des atomes de carbone se combinent avec des atomes de métal. Dans les aciers inoxydables, chrome Les carbures sont les plus courants et se forment surtout sous l'effet de la chaleur. Ils peuvent apparaître dans les joints de grains et modifier les propriétés du matériau. Parfois, cette modification est néfaste.

L'effet des carbures sur l'acier inoxydable

Les carbures de chrome consomment du chrome. En puisant le chrome dans les zones environnantes, celles-ci perdent leur résistance à la corrosion. Le matériau devient alors vulnérable aux attaques, ce que l'on appelle la sensibilisation.

Le réseau de carbure rend l'acier inoxydable fragile et réduit sa ductilité. Il augmente le risque de fissuration sous contrainte. Cela peut compromettre l'intégrité mécanique du matériau.

La formation de carbure réduit la ténacité. Cela signifie que le matériau absorbe moins d'énergie avant de se rompre. Cette caractéristique est essentielle dans les applications soumises à des chocs.

Des carbures se forment pendant le soudage, ce qui affecte la zone affectée thermiquement (HAZ). Cela peut entraîner une corrosion intergranulaire après le soudage, c'est pourquoi il est essentiel de choisir la bonne méthode de soudage.

Ces effets négatifs réduisent la durée de vie du matériau. Des défaillances se produisent, entraînant des réparations coûteuses et une augmentation des temps d'arrêt.

Quel est un carbure courant dans l'acier inoxydable ?

| Type de carbure | Description | Conditions de formation | Impact primaire |

|---|---|---|---|

| Chrome Carbures | Riche en Cr, contenant du C | Plage de température de sensibilisation (450-850°C) | Corrosion intergranulaire |

| Molybdène Carbures | Riche en Mo, contenant du C | Températures élevées, exposition prolongée | Fragilisation |

| Titane Carbures | Riche en Ti, contenant du C | Pendant la solidification, la stabilisation | Neutralise le carbone |

| Carbures de niobium | Riche en Nb, contenant du C | Pendant la solidification, la stabilisation | Neutralise le carbone |

Ce que nous faisons

Stratégies de contrôle des carbures

| Stratégie | Action | Avantages pour l'acier inoxydable |

|---|---|---|

| Grades à faible teneur en carbone | Utilisation "Catégories "L (par exemple, 304L, 316L) | Réduit la formation de carbure |

| Grades stabilisés | Ajouter du Ti ou du Nb (par exemple, 321, 347, 316Ti) | Le carbone forme des carbures stables |

| Recuit de la solution | Traitement thermique à haute température, refroidissement rapide | Dissout les carbures, rétablit le Cr |

| Soudage correct | Contrôle de l'apport de chaleur, refroidissement rapide | Minimise sensibilisation |

| Traitement post-soudure | Nettoyage, passivation | Restaure la couche protectrice |

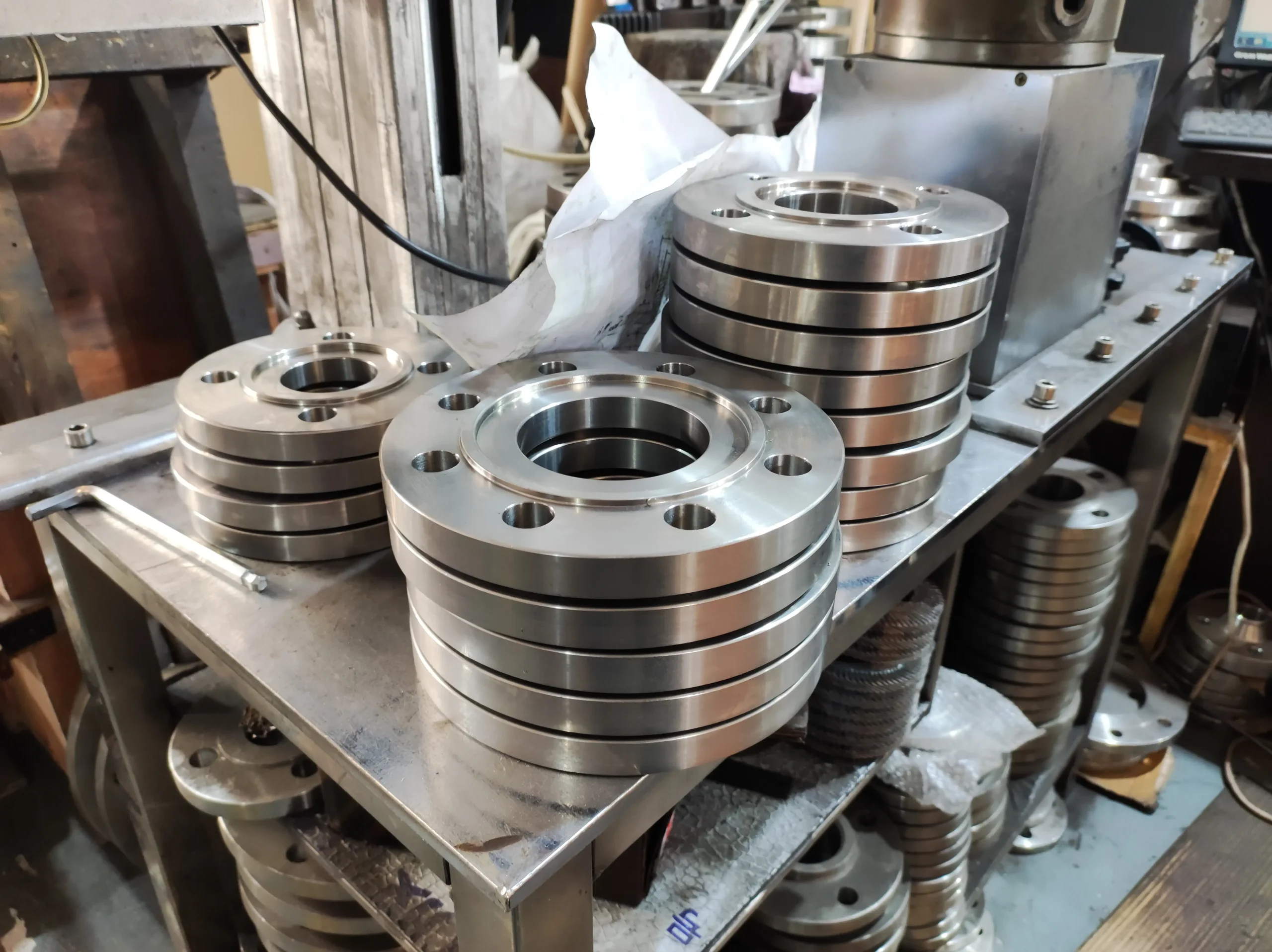

Qu'est-ce que le carbure dans les tuyaux et raccords en acier inoxydable ?

La formation de carbure est un problème majeur pour les tuyaux et les raccords en acier inoxydable. Cela est particulièrement vrai après le soudage.

- Les joints soudés : La zone affectée thermiquement (HAZ) est fragile. Des carbures peuvent se former pendant le soudage, ce qui entraîne des dommages après le soudage. corrosion intergranulaire.

- Service à haute température : Les tuyaux fonctionnant à haute température risquent d'être sensibilisés en cas d'exposition prolongée. Cela peut conduire à une dégradation.

- Environnements corrosifs: Les zones sensibles sont susceptibles d'être érodées et se corrodent plus rapidement que le matériau d'accueil. Cela peut entraîner des fuites et des défaillances.

- Procédés de fabrication : Tout échauffement au cours de la fabrication peut induire des carbures, y compris les opérations de pliage ou de moulage. C'est pourquoi un contrôle adéquat est essentiel.

Approvisionnement en composants fiables

Choisir un un fabricant qui a une grande expérience de l'acier inoxydable et qui comprend ses propriétés uniques. Cela permet d'obtenir des résultats de moulage optimaux.

Recherchez des capacités d'outillage de pointe. L'outillage de précision est essentiel et peut affecter la qualité et l'uniformité des pièces.

Veiller à la rigueur qualité les contrôles sont en place, y compris les contrôles dimensionnels, etc. Vérification de l'intégrité des matériaux et rapports d'essais de matériaux sont également essentiels.

Travailler avec des fabricants réputés qui offrent des produits en acier inoxydable fiables et ont certifications(par exemple ISO 9001 et CE-PED).

Confirmez que le fabricant peut répondre à vos exigences en matière de volume de production. Il doit être en mesure de réaliser des prototypes et de produire des volumes importants.

Vous voudrez peut-être aussi lire :

Que sont les aciers inoxydables H et L - Duplex Pipe

Dégradation des matériaux en acier inoxydable

Qu'est-ce que la déformation par fluage dans l'acier inoxydable ?

Qu'est-ce que le durcissement par vieillissement de l'acier inoxydable ?

Signification des lettres qui suivent les nuances d'acier inoxydable

Acier inoxydable VS acier au carbone : Quelle est la meilleure solution pour les tuyaux et les raccords ?

Comment adoucir l'acier inoxydable ? Quels sont les avantages et les inconvénients ?

Nous contacter

- RM901 No.22 Tangjiaqiao Road Wenzhou Chine

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/