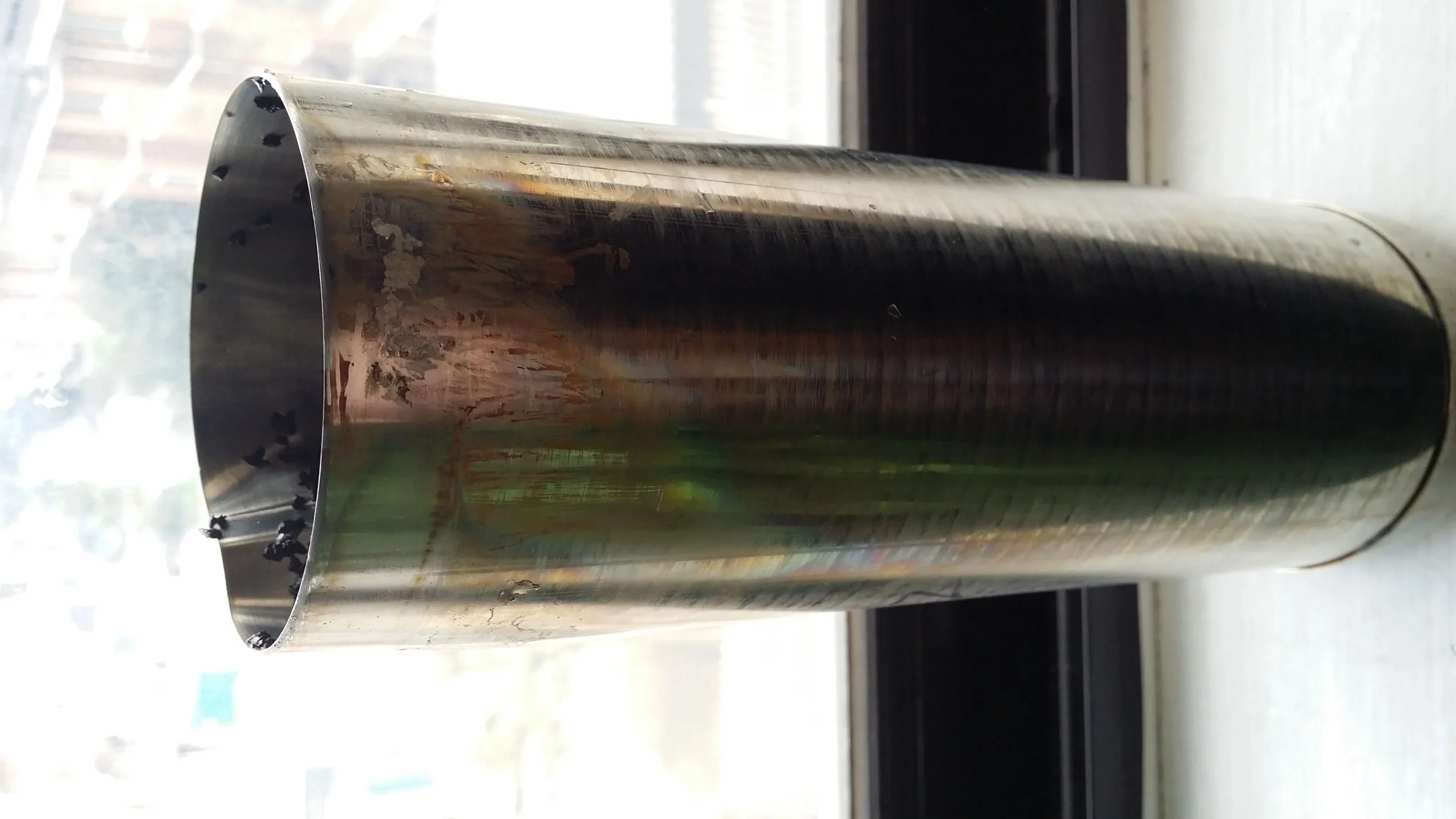

Hastelloy G3 es una aleación de alto rendimiento. Proporciona una solución fiable para la corrosión severa. Estándar tubos de acero inoxidable y accesorios de tubería de acero inoxidable a menudo carece de la resistencia necesaria. Esto es especialmente cierto con los ácidos reductores. Aquí es donde Hastelloy G3 ofrece una solución superior.

Qué es Hastelloy G3 | UNS N06985

El Hastelloy G3 es un aleación de níquel, cromo y hierro. Pertenece al Familia Hastelloy,Hastelloy Serie G. Tiene un alto contenido en níquel y contenido en cromo. Esto le confiere una excelente resistencia. Combate los ácidos clorhídrico, sulfúrico y fosfórico. También ofrece una gran estabilidad térmica. Especialmente a altas temperaturas.

Principales ventajas de Hastelloy G3

El Hastelloy G3 es muy fuerte, resiste los ácidos no oxidantes y maneja bien los ácidos clorhídrico y sulfúrico.

Es estable al calor, resiste la sensibilización. Esto significa que su resistencia a la corrosión se mantiene fuerte después de la soldadura.

Esta aleación es fácil de conformar y soldar. Garantiza uniones fuertes y fiables para sistemas de tuberías.

Composición química

| Elemento | Ni | Cr | Mes | Fe | Co | Minnesota | Si | C |

|---|---|---|---|---|---|---|---|---|

| Contenido (wt%) | Equilibrio | 22.0 – 24.0 | 6.0 – 8.0 | 18.0 – 20.0 | 2,0 Máx | 1,0 Máx | 1,0 Máx | 0,015 Máx |

Propiedades mecánicas

| Propiedad | Fuerza de Tensión | Límite elástico (0.2% Offset) | Alargamiento | Dureza | Densidad |

|---|---|---|---|---|---|

| Valor (típico) | ≥690MPa(100ksi) | ≥350MPa(51ksi) | ≥40 | ≤210 | 8,30 g/cm³ |

Hastelloy G3 VS Acero inoxidable sensibilizado

| Propiedad | Hastelloy G3 (soldado) | Acero inoxidable sensibilizado (Soldado) |

|---|---|---|

| Resistencia a la corrosión | Excelente | Pobre (en la zona de soldadura) |

| Integridad de la zona de soldadura | Fuerte, estable | Quebradizo, débil |

| Vulnerabilidad | Bajo | Alta |

Hastelloy G3 en sistemas de tuberías

- Procesamiento químico: Utilizado para manipular ácido clorhídrico, resiste la ebullición del ácido sulfúrico.

- Control de la contaminación: Utilizado en sistemas de desulfuración de gases de combustión, resiste condensados ácidos altamente corrosivos.

- Industria agroquímica: Pesticidas y fertilizantes agresivos. Esta aleación resiste una amplia gama de productos químicos.

- Sistemas de alta temperatura: Ejes, valvulasy elementos de fijación. Mantiene sus propiedades a altas temperaturas, la estabilidad térmica es un factor clave.

- Sistemas de tuberías:Tuberías y accesorios. Estas piezas necesitan una resistencia extrema a la corrosión.

Suministro y fabricación de Hastelloy G3

Pida siempre un Informe de ensayo de materiales (MTR). Esto demuestra que el material es el que debe ser.

Trabajar con proveedores especializados en tubos y accesorios de acero inoxidable. Conocen estos aceros aleados y pueden garantizar una fabricación y un control de calidad adecuados. ISO 9001 y CE-PED certificado.

Esta aleación necesita métodos específicos de soldadura. Asegúrese de que su equipo sabe cómo manejarlo.

Es más caro de entrada. Pero dura mucho más. Esto le ahorra dinero a largo plazo.

Puede que también quiera leer:

Aleación 625 VS Hastelloy C276

Domine los productos químicos agresivos con Hastelloy C22.

El resumen más completo Preste atención a estos nueve puntos clave sobre la soldadura de Hastelloy C-276.

¿Cuál es la diferencia entre Hastelloy C22 y C276?

Descripción general de la aleación Hastelloy B2

Hastelloy C4 | UNS N06455 Un caballo de batalla estable en sistemas de tuberías de alta presión

Hastelloy C2000 | Propiedades | La nueva superaleación

Hastelloy C59 | UNS N06059 Desbloquear la resistencia máxima

¿Qué es el Hastelloy B3 y cómo combate los ácidos fuertes?

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/