Hastelloy B3 is a high-performance alloy that provides a reliable solution for severe corrosion. Standard tubos de acero inoxidable y accesorios de tubería de acero inoxidable often lacks the needed endurance. This is especially true with reducing acids. This is where Hastelloy B3 offers a superior solution.

What is Hastelloy B3 | UNS N10675

Hastelloy B3 is a aleación a base de níquel which belongs to the Hastelloy family. It has a high nickel and molybdenum content, this gives it excellent resistance.It resists corrosion from hydrochloric acid, sulfuric acid, and phosphoric acid while exhibiting excellent thermal stability. This is especially true at high temperatures and makes Hastelloy B3 a top choice.

Key Advantages of Hastelloy B3

Hastelloy B3 is very strong. It resists non-oxidizing acids and handles hydrochloric and sulfuric acids well.

It is stable under heat. It resists sensitization. This means its corrosion resistance stays strong after welding. This is a key feature for fabricated systems.

This alloy is easy to form. It can be readily welded. This is crucial for complex fabrications. It ensures strong, reliable joints for piping systems.

Previene agrietamiento por corrosión bajo tensión en entornos difíciles. This is vital in chloride-rich solutions. It ensures system integrity under stress.

Composición química

| Elemento | Ni | Mes | Cr | Fe | Co | Minnesota | Si | C |

|---|---|---|---|---|---|---|---|---|

| Content (wt%) | Equilibrio | 27.0 – 32.0 | 1.0 – 3.0 | 1.5 Max | 3.0 Max | 3.0 Max | 0.20 Max | 0.01 Max |

Propiedades mecánicas

| Propiedad | Fuerza de Tensión | Límite elástico (0.2% Offset) | Alargamiento | Dureza | Densidad |

|---|---|---|---|---|---|

| Value (Typical) | ≥760MPa(110ksi) | ≥350MPa(51ksi) | ≥40 | ≤210 | 9.22g/cm³ |

Hastelloy B3 VS Sensitized Stainless Steel

| Propiedad | Hastelloy B3 (Welded) | Sensitized Stainless Steel (Welded) |

|---|---|---|

| Resistencia a la corrosión | Excellent | Poor (in weld zone) |

| Weld Zone Integrity | Strong, stable | Brittle, weak |

| Vulnerability | Bajo | Alta |

Hastelloy B3 in High Pressure Piping Systems

- Chemical Processing: Handles hydrochloric acid and withstands boiling sulfuric acid, significantly extending equipment lifespan.

- Pollution Control: Desulfurization systems resist highly corrosive acidic condensates, ensuring long-term structural integrity.

- Agricultural Chemical Industry: Powerful pesticides and fertilizers. This alloy resists corrosion from multiple chemicals.

- High-Temperature Systems: Shafts, valves, and fasteners. Maintains stable performance in high-temperature environments, with thermal stability as a key advantage.

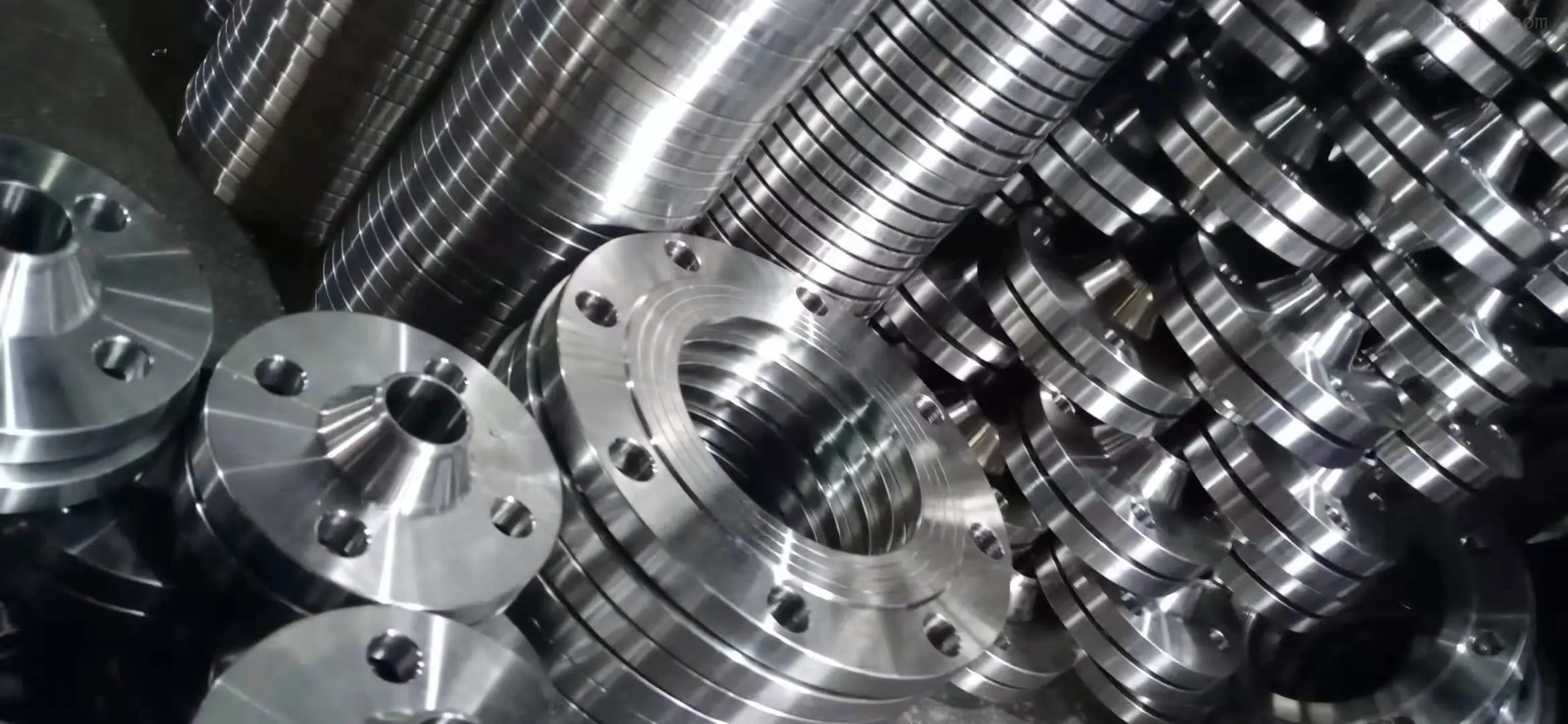

- Piping Systems: Key stainless steel pipe fittings. These components require exceptional corrosion resistance to guarantee system integrity.

Sourcing and Fabricating Hastelloy B3

A complete Informe de ensayo de materiales (MTR) is required. It verifies the precise composition of the alloy and ensures its performance.

Trabajar con specialized suppliers of stainless steel pipe and fittings. They understand these alloy steels and can ensure proper fabrication and quality control,and are ISO 9001 y CE-PED certified.

This alloy requires specific procedures. Proper welding technique ensures the integrity of the weld.

It is expensive, so it is important to assess whether the product has a longer service life. This can justify its higher initial cost.

Puede que también quiera leer:

Alloy 625 VS Hastelloy C276

Domine los productos químicos agresivos con Hastelloy C22.

El resumen más completo Preste atención a estos nueve puntos clave sobre la soldadura de Hastelloy C-276.

¿Cuál es la diferencia entre Hastelloy C22 y C276?

Descripción general de la aleación Hastelloy B2

Hastelloy C4 | UNS N06455 A Stable Workhorse in High Pressure Pipe Systems

Hastelloy C2000 | Properties | The Next-Gen Superalloy

Hastelloy C59 | UNS N06059 Unlock Ultimate Resistance

What is Hastelloy B4 and How Does it Prevent Stress Cracking?

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/