Sanitary pipe fittings must meet the standards for cleanliness. This is because of the high hygiene requirements of the environment in which they are located. Obtaining cleanliness standards ensures that your accesorios de acero inoxidable have truly hygienic properties.

What Are Standards for Cleanliness? A Benchmark for Hygiene!

Cleanliness standards are vital guidelines. They define acceptable levels of purity, surface treatments, design and manufacturing methods. These standards prevent microbial growth and minimise product residues. This is vital for industries such as food, pharmaceutical and biotechnology. They ensure that your sanitaryware performs as expected.

Main Pillars of The Cleanliness Standards

Standards require a very low surface roughness (Ra) to prevent bacterial adhesion. It also makes cleaning easier.

Fittings must avoid internal seams, which can trap contaminants in hidden areas. The standard ensures a seamless internal profile, eliminating potential conditions for microbial growth.

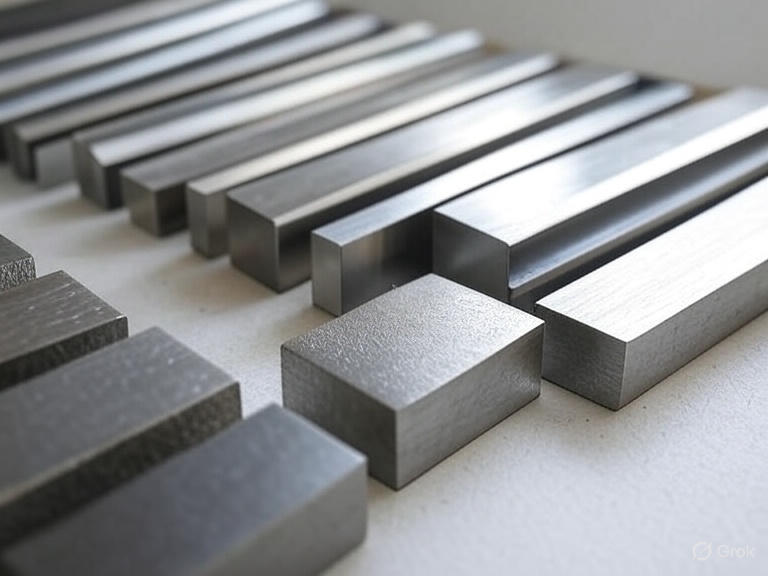

Only specific corrosion-resistant materials are allowed. Commonly used are grades of stainless steel such as 304L steel y 316L steel.

The design must allow for the complete drainage of liquids, with no liquid residue. This prevents stagnant areas and also ensures an effective clean-in-place (CIP) process.

Components should be easy to inspect, which helps detect any contamination.

Key Cleanliness Standards & Their Focus

| Standard Name | Organización | Primary Focus | Target Industries |

|---|---|---|---|

| 3-A Sanitary Standards | 3-A Sanitary Std., Inc. | Hygienic design, fabrication, processing equipment | Food, Pharma, Biotech |

| ASME BPE | ASME | Bioprocessing Equipment design, materials, fabrication | Biotech, Pharma |

| ISO 2853 | ISO | Clamp connections, dimensions for food industry | Food, Beverage |

| EHEDG Guidelines | EHEDG | Hygienic engineering & design principles | Food, Pharma, Cosmetics |

Qué hacemos

Surface Roughness (Ra) Targets for Sanitary Fittings

| Finish Method | Target Ra (µin / µm) | Application Level |

|---|---|---|

| Mechanical Polish | 20-32 µin (0.5-0.8 µm) | General food, beverage |

| Fine Mechanical Polish | 15-20 µin (0.38-0.5 µm) | Dairy, some pharma |

| Electropolished | <15 µin (often <10 µin) | Biotech, sterile processes, ultra-pure |

| As-Welded (Internal) | Must be smooth / purged | Orbital welding for internal welds |

Impact of Cleanliness Standards on SS Pipe and Fittings

- Reduced Biofilm Formation: Smooth surfaces prevent microbial adhesion, minimising the risk of contamination and maintaining product quality.

- Efficient Cleaning Cycle: The seamless design allows the cleaner to reach all areas.

- Enhanced Corrosion Resistance: Proper surface preparation and material quality protect against localised corrosion. This extends the service life of components.

- Increased Product Yield: Minimising the risk of contamination improves product purity and maximises yield.

Puede que también quiera leer:

Descubra qué son los accesorios de tubería y por qué son importantes.

How To Choose The Right Sanitary Pipes And Fittings

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/