Nimonic 75 es una solución fiable para temperaturas extremas. La resistencia al calor de esta aleación de alto rendimiento es muy superior a la de los aceros inoxidables estándar. Sus propiedades únicas son fundamentales para la durabilidad a largo plazo. La elección de Nimonic 75 garantiza que sus productos críticos tubos de acero inoxidable y accesorios de tubería de acero inoxidable mantener su fuerza y funcionalidad.

Nimonic 75 | UNS N06075

El Nimonic 75 es un aleación a base de níquel perteneciente al grupo Aleación Nimonicque contiene alrededor de 20% cromo por lo que tiene una excelente resistencia a la oxidación. Tiene buenas propiedades mecánicas a altas temperaturas.

Puntos fuertes de Nimonic 75

Nimonic 75 es resistente a la oxidación y puede soportar temperaturas de funcionamiento continuo de hasta 980°C (1795°F).

Mantiene la resistencia a temperaturas elevadas para un rendimiento fiable. No está diseñado para resistir deformación por fluencia. Sin embargo, presenta una buena integridad mecánica en muchas aplicaciones.

El Nimonic 75 es fácil de moldear y soldar, y se adapta bien a fabricaciones complejas.

Conserva sus propiedades cuando se somete al calor y no pierde resistencia rápidamente, por lo que es ideal para aplicaciones a altas temperaturas.

Composición química

| Elemento | Ni | Cr | Fe | C | Ti | Cu | Minnesota | Si |

|---|---|---|---|---|---|---|---|---|

| Contenido (wt%) | Equilibrio | 18.0-21.0 | 5,0 Máx | 0.08-0.15 | 0.20-0.60 | 0,5 Máx | 1,0 Máx | 1,0 Máx |

Propiedades mecánicas

| Propiedad | Fuerza de Tensión | Límite elástico (0.2% Offset) | Alargamiento | Dureza | Densidad | Intervalo de fusión |

|---|---|---|---|---|---|---|

| Valor (típico) | ≥690MPa(100ksi) | ≥275MPa(40ksi) | ≥30 | 200 Máx | 8,26 g/cm³ | 1370-1420 ℃ |

Nimonic 75 en sistemas de tuberías de alta temperatura

- Tubos de llama: Soportan altas temperaturas y pueden utilizarse para tubos de llama.

- Sistemas de escape: Pueden manejar corrientes de gases calientes, resisten la oxidación y la corrosión y pueden utilizarse en colectores de escape.

- Tubos y fuelles: Estos materiales pueden soportar ciclos térmicos y se fabrican en tubos de alta temperatura y fuelles de expansión.

- Componentes de hornos: Soportan altas temperaturas sostenidas y evitan la formación de incrustaciones en revestimientos y cubiertas de hornos.

- Sistemas de tuberías: Pueden utilizarse para accesorios críticos de acero inoxidable en los que se requiera una resistencia extrema al calor.

Aprovisionamiento y fabricación de Nimonic 75

Un completo Informe de ensayo de materiales (MTR). Verifica la composición precisa de la aleación y garantiza su rendimiento.

Trabajar con proveedores especializados en tubos y accesorios de acero inoxidable. Conocen estos aceros aleados y pueden garantizar una fabricación y un control de calidad adecuados. ISO 9001 y CE-PED certificado.

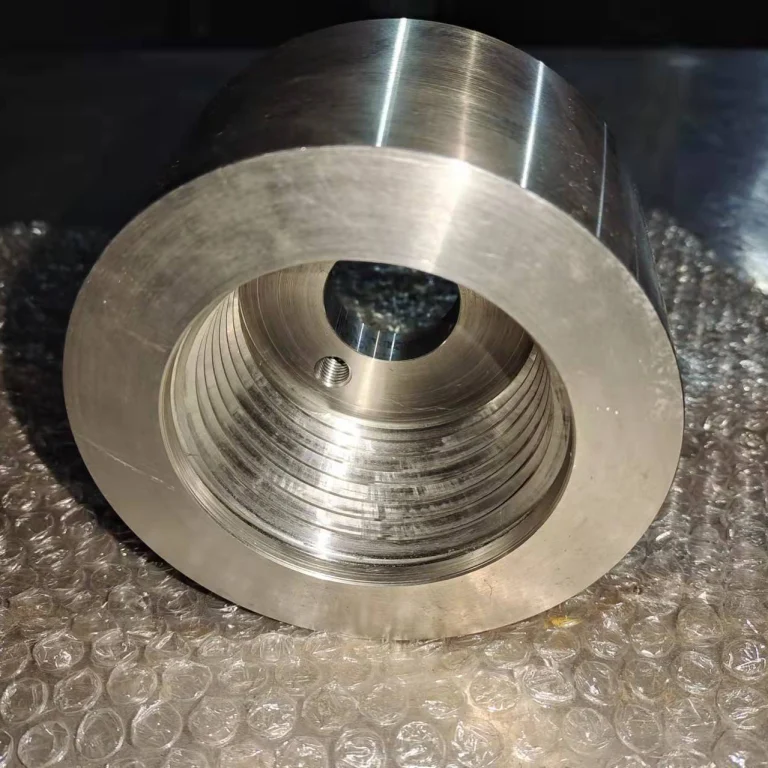

Es difícil de mecanizar y requiere herramientas especiales. Las técnicas de soldadura específicas son esenciales para garantizar la integridad de la soldadura.

Es caro, por lo que es importante evaluar si el producto tiene una vida útil más larga. Esto puede justificar su mayor coste inicial.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/