Hastelloy G stands as a family of nickel-chromium-iron-molybdenum alloys.It provides superb corrosion resistance in a wide range of chemical environments.A top choice emerges for applications where standard tubos de acero inoxidable o accesorios de tubería de acero inoxidable fracasaría.

Introduction to the Hastelloy G Series

Qué es la aleación Hastelloy

Aleación Hastelloy contains a high proportion of nickel, and also contains chromium and molybdenum. The family includes three main series. They are the B series, C series, and G series. Each is designed for specific environments.

Qué hacemos

- Plato

- Hoja

- Piezas forjadas

- Barra redonda

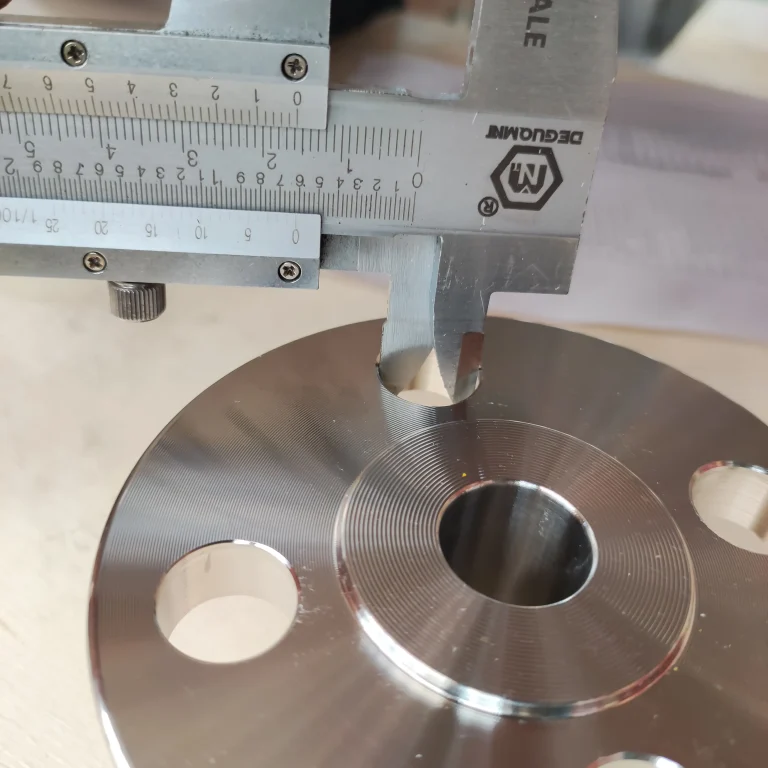

- Brida

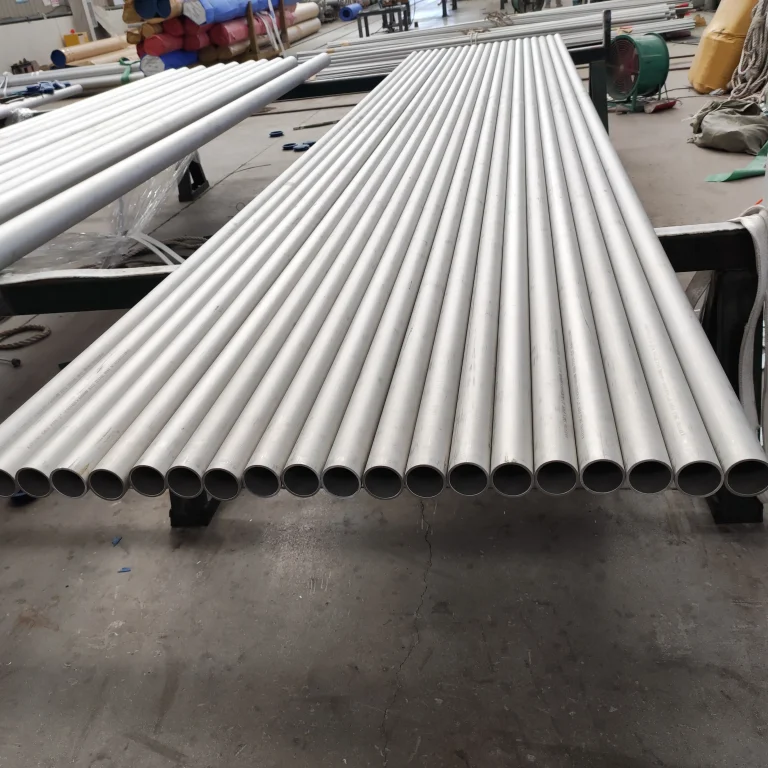

- Tuberías

- Accesorios

- Personalizado

Más información

Key Advantages of Hastelloy G Series

A mix of acids is handled well by this alloy. Resistance to both oxidizing and reducing media is a key benefit. Superior performance is delivered against sulfuric and phosphoric acids.

Corrosión por picadura y corrosión en grietas are actively fought by the alloy’s composition. For this reason, it is often a better option than many stainless steels.

Easy fabrication is a major benefit. Strong welds are formed without losing properties. Complex pipes and fittings are thus simpler to create.

A low carbon content prevents sensibilización after welding. This ensures the alloy retains its corrosion resistance. The material performs well in the heat-affected zone.

Key Disadvantages of Hastelloy G Series

The composition contains expensive nickel and molybdenum, whose addition drives up the price.

This alloy material has a high density, which increases the system’s weight. Its high-density characteristics must be considered during design and support structure planning.

High hardness leads to machining difficulties, requiring specialized tools and machining speeds, thereby increasing manufacturing time and costs.

Good high-temperature resistance is present in the alloy. However, a primary choice for high-strength, high-temperature applications is not a role it plays. The alloy lacks the properties of other superalloys for structural use at high heat.

The Natural Degradation Process of Hastelloy G

- Creep and Stress Fracture: High temperatures and sustained stress can cause slow, permanent deformation known as creep. Over time, this may ultimately lead to failure. Alloy strength gradually diminishes with prolonged exposure.

- Fatigue: Repeated stress cycles may induce microcracks in components. These cracks progressively propagate, eventually causing component failure.

- Long-Term Corrosion: Despite high corrosion resistance, prolonged exposure to highly corrosive chemicals can degrade the material. Over time, pitting corrosion or surface thinning may occur. While extremely slow, this process is a natural phenomenon within the alloy’s lifecycle.

- Erosion-Corrosion: Environments involving high-velocity fluid flow induce a specific form of degradation. The combined effects of erosion and corrosion continuously wear down the alloy, potentially shortening its service life in certain applications.

Common Hastelloy G Grades

| Calificación | Elementos clave | Ventaja principal |

|---|---|---|

| Hastelloy G3 | Cr/Fe/Mo | Welds easily, resists pitting |

| Hastelloy G30 | Cr/Fe/Mo | Phosphoric acid resistance |

| Hastelloy G35 | Cr/Fe/Mo | High strength, resists chlorides |

| Hastelloy G50 | Cr/Fe/Mo | Good for high-temp sulfuric acid |

Hastelloy G VS Stainless Steel

| Característica | Hastelloy G | Acero inoxidable |

|---|---|---|

| Mixed Acids | Excelente | Pobre |

| Pitting and Crevice Corrosion | Excelente | Bien |

| Resistencia a los cloruros | Excelente | Bien |

| Coste | Muy alta | Medio |

| Uso principal | Phosphoric Acid Environments | Resistencia general a la corrosión |

Hastelloy G Series in Piping Systems

- Chemical Processing: Extreme corrosion resistance is provided by Hastelloy G for critical stainless steel pipe fittings. Your system works perfectly, even with aggressive acid mixtures.

- Fertilizer Production: The alloy is perfect for handling wet-process phosphoric acid. It withstands highly corrosive chemicals. Efficient and safe operation is ensured by its use.

- Flue Gas Desulfurization: A key use for this alloy. It resists corrosive environments found in power plants. Its high resistance protects pipes and fittings.

- Waste Treatment: The material is essential for pipes and fittings in waste treatment. Hastelloy G handles corrosive chemicals. The alloy maintains its integrity. This prevents leaks and costly downtime.

Suministro y fabricación de aleaciones Hastelloy

Un completo Informe de ensayo de materiales (MTR). Verifica la composición precisa de la aleación y garantiza su rendimiento.

Trabajar con proveedores especializados en tubos y accesorios de acero inoxidable. Conocen estos aceros aleados y pueden garantizar una fabricación y un control de calidad adecuados. ISO 9001 y CE-PED certificado.

Esta aleación requiere procedimientos específicos. Una técnica de soldadura adecuada garantiza la integridad de la soldadura.

Es caro, por lo que es importante evaluar si el producto tiene una vida útil más larga. Esto puede justificar su mayor coste inicial.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/