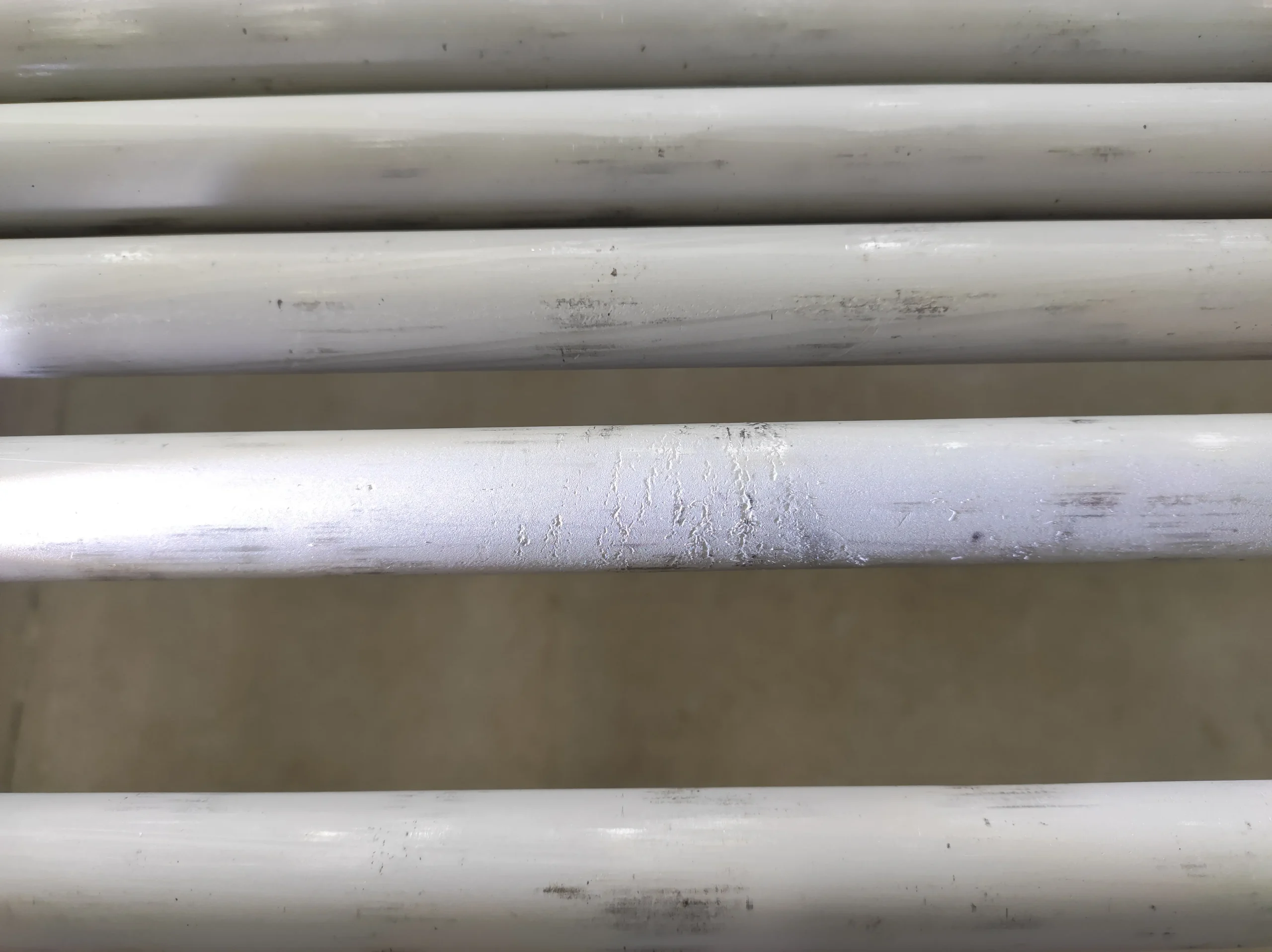

La presencia de Incoloy 805 hace que los entornos duros y de altas temperaturas sean una amenaza menor. En este escenario, el acero inoxidable estándar no suele ser suficiente. Sepamos por qué la aleación 805 es la mejor elección. Tiene sentido utilizarlo para componentes críticos como las especialidades tubería de acero inoxidable y accesorios.

¿Qué es Incoloy 805? Una elección estratégica de material

El Incoloy 805 (UNS N08805) es un material de alto rendimiento. aleación de níquel, hierro y cromo. Diseñado para aplicaciones severas. Presenta una excelente resistencia a la carburación. Además, es resistente a la oxidación y la vulcanización. Estas condiciones agresivas suelen darse a temperaturas muy elevadas. Una característica clave es su excelente resistencia a la fluencia. Mantiene una estructura metalúrgica estable. Esto garantiza su integridad a largo plazo. Su rendimiento es superior al de muchos aceros inoxidables convencionales.

Principales ventajas de Incoloy 805

Incoloy 805 ofrece ventajas convincentes a los compradores e ingenieros más exigentes. Su robustez aumenta la fiabilidad del sistema y reduce el mantenimiento.

Destaca en atmósferas de alta temperatura y ricas en carbono. Forma una capa de óxido estable que impide que el carbono se difunda en el material. Esto es vital para los hornos tubos y tubos convertidores.

Esta aleación es resistente a la oxidación incluso a temperaturas extremas. Su película estable de óxido de cromo le proporciona protección. Esto garantiza su longevidad en el aire o en entornos ricos en oxígeno. Es importante para los sistemas de escape de alta temperatura.

La aleación 805 mantiene su resistencia bajo esfuerzos prolongados. Resiste la deformación a temperaturas elevadas. Esto proporciona integridad estructural a componentes críticos. Piense en tuberías y accesorios sometidos a presión.

Los entornos que contienen azufre pueden degradar gravemente el rendimiento de los metales, e Incoloy 805 proporciona una fuerte protección. Puede soportar estos duros entornos y prolongar la vida útil de las tuberías procesadas con azufre.

A diferencia de algunas aleaciones de alta temperatura, Incoloy 805 no forma fases frágiles. Mantiene la ductilidad y la resistencia, garantizando la integridad operativa a largo plazo. Reduce el riesgo de fallos repentinos.

Composición química de Incoloy 805

| Elemento | Ni | Cr | Fe | C | Minnesota | Si | Alabama | Ti | Nótese bien | S |

|---|---|---|---|---|---|---|---|---|---|---|

| Contenido (%) | 30.0-33.0 | 26.0-29.0 | Equilibrio | ≤0.05 | ≤1.00 | ≤1.00 | ≤0.10 | ≤0.10 | 0.80-1.20 | ≤0.015 |

Qué hacemos

Propiedades mecánicas de Incoloy 805

| Fuerza de Tensión | Límite elástico (0.2% Offset) | Alargamiento (en 50 mm) | Dureza (HB) | Densidad | Intervalo de fusión |

|---|---|---|---|---|---|

| ≥600MPa ( ≥87ksi ) | ≥240MPa ( ≥35ksi ) | ≥30 | ≤200 | 7,99 g/cm³ | 1370-1410°C |

Sistemas de tuberías y accesorios de acero inoxidable

Aunque el acero inoxidable es habitual, el Incoloy 805 ofrece un rendimiento superior. Sobresale donde el acero inoxidable fallaría. Es crucial para prolongar la vida útil en condiciones de proceso extremas.

Incoloy 805 es la columna vertebral del reformador tubos en la producción de hidrógeno o amoníaco. Soporta temperaturas extremas y gases corrosivos para garantizar un funcionamiento eficaz y seguro.

Estas bobinas están diseñadas para soportar los rigores del entorno de carburación. La aleación 805 tiene una excelente resistencia a la corrosión, lo que evita la formación de coque y prolonga el tiempo de funcionamiento. Mayor eficacia.

Son habituales las altas temperaturas y los gases residuales agresivos. Los tubos y accesorios de aleación 805 son resistentes a la oxidación y la vulcanización. Garantiza una eliminación fiable de los residuos.

El tubo Incoloy 805 es importante para el intercambio de calor crítico en corrientes de agua caliente y corrosiva. Mantiene la integridad donde otras aleaciones se degradarían.

Formas comunes de los productos y normas aplicables

| Forma del producto | Correspondiente ASTM/Normas ASME |

|---|---|

| Tubos sin soldadura | ASTM B535 (cubre tubos y tuberías), ASME SB535 |

| Tubos soldados | ASTM B546 (cubre tubos y tuberías), ASME SB546 |

| Accesorios de tuberia | ASTM B366 (Norma general de accesorios; se aplican grados específicos) |

| Chapas, hojas y tiras | ASTM B463, ASME SB463 |

| Bar y Varilla | ASTM B473, ASME SB473 |

| Piezas forjadas | ASTM B564 |

Mejores prácticas de soldadura para sistemas Incoloy 805

Las técnicas de soldadura adecuadas son fundamentales para Incoloy 805 tubo de acero inoxidable soldado así como accesorios. Garantizan la integridad y el rendimiento del conjunto final.

- Selección del metal de aportación: Utilice un metal de aportación adecuado. AWS A5.14 ERNiCrCoMo-1 (similar a Inconel 617 o rellenos tipo 617). De este modo se garantiza una corrosión-Soldaduras resistentes.

- Preparación de la superficie: Limpiar a fondo todas las superficies de soldadura. Elimine toda la cascarilla, aceite o grasa. Esto evita la contaminación y los defectos de soldadura.

- Baja entrada de calor: Mantener un bajo aporte de calor durante la soldadura. Evitar temperaturas excesivas entre pasadas. Esto minimiza la distorsión y preserva las propiedades del material.

- Gas de protección: Utilice un gas de protección inerte como el argón. Esto protege el baño de soldadura de la contaminación atmosférica. Esto garantiza soldaduras limpias y sin defectos.

- Sin tratamiento térmico posterior a la soldadura: Generalmente, post-soldadura tratamiento térmico no es necesario. Incoloy 805 resiste sensibilización. Esto simplifica los procesos de fabricación.

Incoloy 805 vs. Incoloy 800: Principales diferencias

| Característica | Incoloy 805 | Incoloy 800 |

|---|---|---|

| Fuerza primaria | Carburización, sulfuración | Oxidación, corrosión acuosa |

| Contenido en cromo | Superior (26-29%) | Inferior (19-23%) |

| Elemento clave añadido | Niobio | Titanio/Aluminio (menor) |

Puede que también quiera leer:

Diferencias entre la aleación 800, 800H y 800HT

Incoloy 800H Details:¿Para qué se utiliza?

Qué es Incoloy 800HT : Creep Fighter

Dominio del Incoloy 800 para aplicaciones exigentes

¿Cómo protege Incoloy 925 los sistemas de tuberías críticos?

¿Cómo protege Incoloy 925 los sistemas de tuberías críticos?

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/