Alloy 625 VS Hastelloy C276, what is the difference? They both have amazing corrosion resistance. When your piping system requires optimal performance and standard stainless steel simply won’t cut it, compare the differences between the two to find the better choice. Ensure that your tubos de acero inoxidable y accesorios de tubería de acero inoxidable están hechos para durar.

What Are Alloy 625 and Hastelloy C276? Elite Performers!

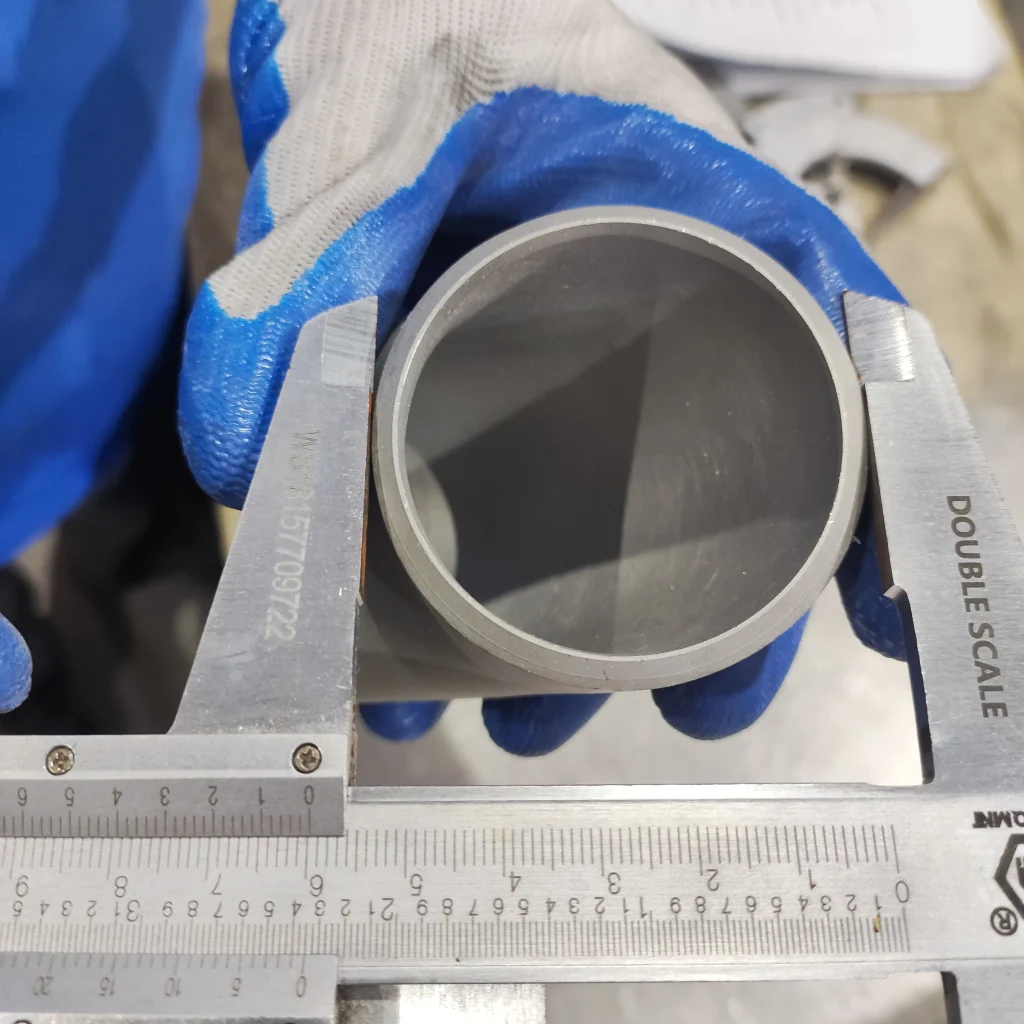

Alloy 625 Pipe | N06625 | W.Nr. 2.4856 Nickel Alloy Pipe & Tube es un nickel-chromium-molybdenum alloy. It is characterized by high strength and has a wide range of corrosion resistance. It excels in many aggressive media.

Hastelloy C276 (UNS N10276, EN 2.4819) is also a nickel-chromium-molybdenum alloy. It has a high molibdeno and tungsten content, which gives it exceptional corrosion resistance. It excels in extremely corrosive environments.

Alloy 625 VS Hastelloy C276: Key Differentiators

Alloy 625 has a wide range of corrosion resistance and handles oxidizing and reducing acids well. Hastelloy C276 has excellent corrosion resistance and performs well in aggressive oxidizing and reducing media, including wet chlorine.

Alloy 625 has higher strength and performs well from low temperatures to 1000 ℃. Hastelloy C276 also has excellent high-temperature strength and resists corrosion at extreme temperatures.

Hastelloy C276 has a high molybdenum and tungsten content, which greatly increases resistance to picaduras y corrosión en grietas. This gives C276 an advantage in very specialized and harsh environments.

Both have high weldability. Hastelloy C276 is slightly more difficult to weld due to its high alloy content. Proper procedimientos de soldadura are critical for both. The lower carbon version improves post weld integrity.

In general, Hastelloy C276 is more expensive due to its unique composition and excellent wear resistance.

Global Designations: Alloy 625 VS Hastelloy C276

| Cuerpo estándar | Alloy 625 Designation | Hastelloy C276 Designation |

|---|---|---|

| UNS | N06625 | N10276 |

| ES | 2.4856 | 2.4819 |

| ASTM/ASME | B443, B444, B474, etc. | B575, B574, B619, etc. |

| ISO | 6208 | 15156-3 |

| GB (China) | NS3306 | NS3304 |

Key Chemical Composition: Alloy 625 VS Hastelloy C276

| Elemento | Ni | Cr | Mes | W | Fe | Nótese bien | C |

|---|---|---|---|---|---|---|---|

| Aleación 625 | ≥58.0 | 20.0-23.0 | 8.0-10.0 | ≤0.35 | ≤5.0 | 3.15-4.15 | ≤0.10 |

| Hastelloy C276 | Balance (Min 53.0) | 14.5-16.5 | 15.0-17.0 | 3.0-4.5 | 4.0-7.0 | N / A | ≤0.01 |

Mechanical Properties: Alloy 625 VS Hastelloy C276

| Propiedad | Fuerza de Tensión | Fuerza de producción | Alargamiento | Densidad |

|---|---|---|---|---|

| Aleación 625 | ≥827 MPa (120 ksi) | ≥414 MPa (60 ksi) | ≥30% | 8.43g/cm³ |

| Hastelloy C276 | ≥690MPa (100 ksi) | ≥275MPa (40 ksi) | ≥40% | 8.89g/cm³ |

Applications in Stainless Steel Pipe and Fittings

- Alloy 625: Chemical processing (sulfuric acid, nitric acid), aerospace (engine components), marine (seawater components) and pollution control (flue gas desulfurization systems).

- Hastelloy C276: For use in extremely ambientes corrosivos. This includes wet chlorine gas, hypochlorite solutions and highly oxidizing acid mixtures. Commonly used in pharmaceutical reactors, waste treatment and sour gas treatment.

- Piping Systems: These two alloys make important tubería y accesorios de acero inoxidable. They handle corrosive fluids and can withstand high pressures and temperatures.

Puede que también quiera leer:

Tabla comparativa de aleaciones y calidades de níquel en varias regiones

¿Cuál es la diferencia entre Hastelloy C22 y C276?

Domine los productos químicos agresivos con Hastelloy C22.

El resumen más completo Preste atención a estos nueve puntos clave sobre la soldadura de Hastelloy C-276.

Descripción general de la aleación Hastelloy B2

Hastelloy C4 | UNS N06455 A Stable Workhorse in High Pressure Pipe Systems

Hastelloy C59 | UNS N06059 Unlock Ultimate Resistance

Hastelloy C2000 | Properties | The Next-Gen Superalloy

What is Hastelloy B3 and How Does it Fight Strong Acids?

What is Hastelloy B4 and How Does it Prevent Stress Cracking?

What Is Hastelloy G3? A Versatile Corrosion Fighter!

What is Hastelloy G35 and How Does it Conquer Corrosive Acids?

What is Hastelloy G50 and How to Use it for Critical Piping?

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/