Tubería SCH 40

SCH 40 pipe refers to a standard medium-wall-thickness pipe designed for medium-pressure applications.It is widely used in water supply and drainage,irrigation,and industrial fluid conveyance.Manufactured from polyvinyl chloride (PVC) or carbon steel,this pipe combines strength with versatility.Its wall thickness increases proportionally with nominal pipe diameter.

SCH 40 PVC pipe is suitable for cold water,while steel can withstand higher pressures and is commonly used for water,oil,and gas.“40” denotes a specific standardized wall thickness determined by pipe size.For example,a 3/4-inch SCH 40 pipe has an outside diameter slightly greater than 1 inch and a wall thickness of approximately 1/8 inch.It is widely used in residential plumbing,irrigation,chemical transport,structural support,and fire sprinkler systems.

Schedule 40 pipe is thinner than Schedule 80 pipe.Due to its thicker wall,Schedule 80 can withstand higher pressures.Schedule 80 pipe has a higher PSI rating,while Schedule 40 pipe is more flexible and typically more cost-effective.

- ASME B36.10M

- ASME B36.19M

- ASTM A53 / ASTM A106

- ASTM D1785 / UL 651

¿Tiene alguna necesidad?

Somos un proveedor profesional de tubos SCH 40 y SCH 40S, le invitamos a ponerse en contacto conmigo si tiene algún requisito.

Más información

SCH 40 Pipe Materials

- Acero carbono:

ASTM A53 Grade B:

General-purpose pipe suitable for welding,flanging,or bending,commonly used for water and gas transmission.

ASTM A106 Grade B:

Seamless pipe specifically designed for high-temperature and high-pressure environments,such as refineries or chemical plants.

API 5L Grade B:

Primarily used for long-distance transportation in the oil and gas industry. - Plastic:

PVC:

The most common plastic material.

Complies with ASTM D1785 (Pressure) and ASTM D2665 (Drain/Vent).

Typically has a maximum temperature rating of 60°C (140°F) and is strictly prohibited for compressed air applications.

CPVC:

Offers superior high-temperature resistance compared to PVC, commonly used for industrial hot water or chemically corrosive fluids. - In contrast,stainless steel Tubos SCH 40S are used in scenarios with extremely high requirements for hygiene or corrosion resistance.

Typical Dimensions for ASTM A53 SCH 40 Pipe

| NPS | OD , inch | OD , mm | Wall Thickness , inch | Wall Thickness , mm |

|---|---|---|---|---|

| 1/2 pulg. | 0.840 in. | 21.3 mm | 0.109 in. | 2.77 mm |

| 3/4 in. | 1.050 in. | 26.7 mm | 0.113 in. | 2.87 mm |

| 1 pulg. | 1.315 in. | 33.4 mm | 0.133 in. | 3.38 mm |

| 3/2 in. | 1.900 in. | 48.3 mm | 0.145 in. | 3.68 mm |

| 2 pulg. | 2.375 in. | 60.3 mm | 0.154 in. | 3.91 mm |

| 3 in. | 3.500 in. | 88.9 mm | 0.216 in. | 5.49 mm |

| 4 pulg. | 4.500 in. | 114.3 mm | 0.237 in. | 6.02 mm |

| 6 pulg. | 6.625 in. | 168.3 mm | 0.280 in. | 7.11 mm |

| 8 in. | 8.625 in. | 219.1 mm | 0.322 in. | 8.18 mm |

SCH 40 Pipe Manufacturing Process

Welded Pipe - ERW

- Forming:

Steel coils (strip steel) are gradually curved into a circular shape through a series of rollers. - High-Frequency Resistance Welding (ERW):

High-frequency current generates heat along the edges of the pipe material,fusing the edges together under the pressure of squeeze wheels. - Weld Treatment:

Excess weld beads are trimmed from both the inner and outer surfaces.The weld is then heat-treated (normalized) to align its microstructure with the base material,ensuring structural integrity.

Tubos sin soldadura

- Piercing:

A solid round billet is heated to white-hot temperatures,then pierced through the center using a piercing machine to create an opening. - Extension and Wall Reduction:

Using a continuous rolling mill or pipe piercing machine,the wall thickness is adjusted to precisely meet the SCH 40 wall thickness requirements. - Sizing:

Ensures the outside diameter (OD) meets standard dimensions (e.g., 4“ pipe must be 4.500”) using a sizing machine.

PVC/Plastic Pipe Extrusion Process

- Blending and Melting:

PVC resin,stabilizers,and pigments are blended and heated to melt. - Continuous Extrusion:

The molten plastic is extruded through a ring-shaped die to form a tubular shape. - Vacuum Setting and Cooling:

The material is cooled in a vacuum chamber to ensure precise outer diameter and prevent gravitational collapse.

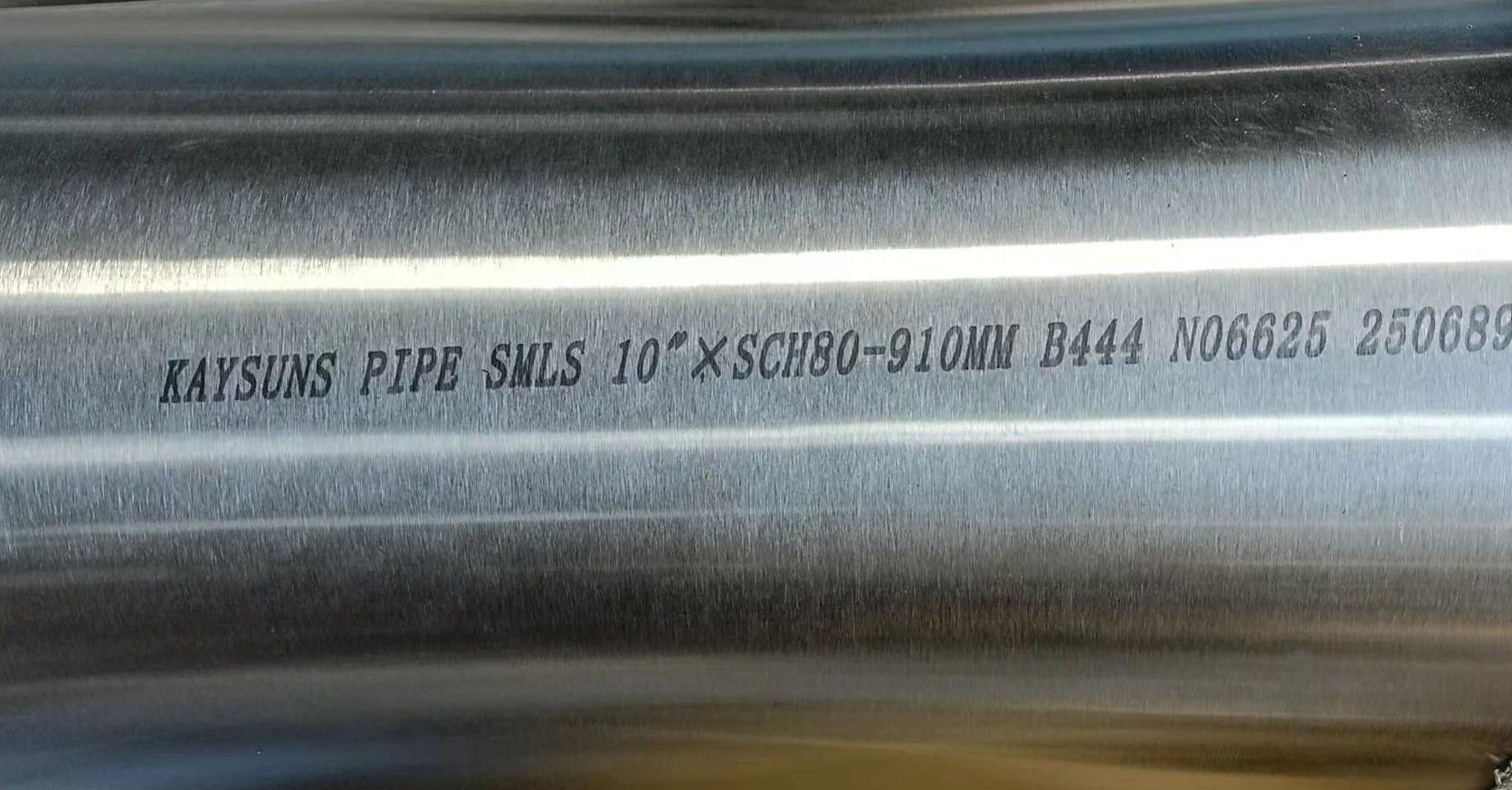

Post-processing

- Galvanizing:

Upon request,Kaysuns will subject SCH 40 steel pipes to a hot-dip galvanizing bath to achieve a corrosion-resistant coating. - Ensayos no destructivos (END):

Verify pipeline integrity under specified working pressure through hydrostatic testing,ultrasonic testing,or eddy current testing. - Marking:

Material,wall thickness designation (SCH 40),and furnace number are spray-printed onto the pipe body per standards such as ASME B36.10M.

SCH 40 Pipe Applications

Carbon Steel / Galvanized Steel Pipe

- Fluid and Gas Conveyance

- HVAC System Piping

- Industria del petróleo y el gas

- Fire Sprinkler Systems

PVC/Plastic Pipe

- Residential and Commercial Plumbing

- Irrigation Systems

- Pools and Spas

- Electrical Conduits

Contacto

Póngase en contacto con nosotros

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/

Encuéntranos