A intercambiador de calor de acero inoxidable Es un dispositivo de transferencia de calor altamente eficiente. Estos sistemas críticos se emplean para transferir energía térmica entre dos fluidos distintos. Es fundamental que estos dos fluidos nunca se mezclen físicamente.

Los equipos son famosos por su durabilidad y resistencia a la corrosión, lo que los convierte en una opción excelente para entornos difíciles.

El papel de un intercambiador de calor de acero inoxidable

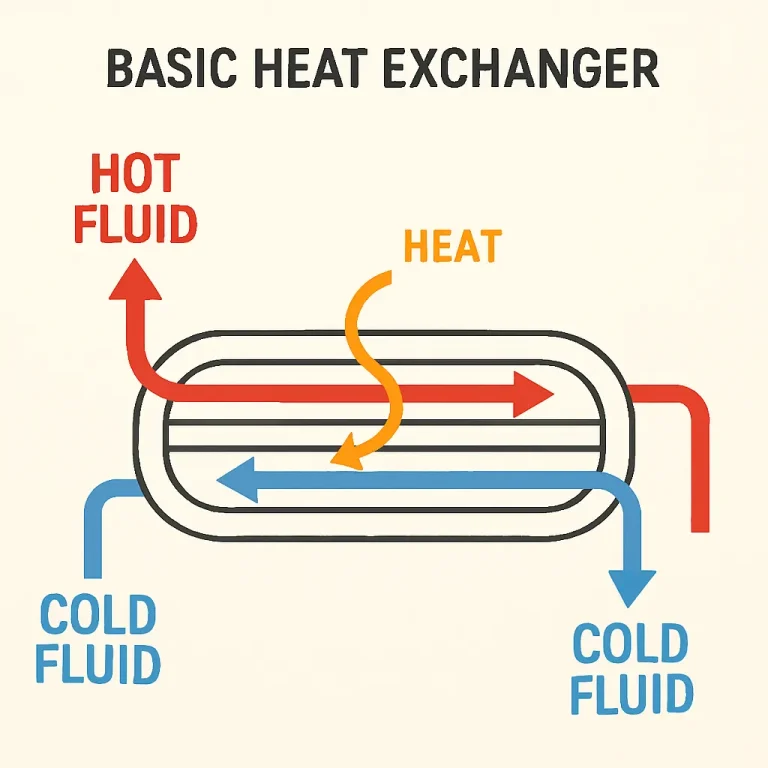

Un intercambiador de calor es fundamental para la gestión térmica. Transfiere el calor de un fluido más caliente a otro más frío. Este proceso es necesario para calentar, enfriar o recuperar energía. Su construcción en acero inoxidable garantiza su integridad. Permite que el intercambio de calor se produzca de forma fiable bajo presión. Se mantiene un alto rendimiento incluso con fluidos de proceso corrosivos.

Principio de funcionamiento

- Separación: Un fluido fluye por un lado de la barrera. El segundo fluido fluye por el lado opuesto. Esto mantiene los dos medios físicamente separados.

- Conducción: El calor se transmite a través de la pared sólida de acero inoxidable. La energía térmica se transmite del fluido más caliente al más frío. El acero inoxidable proporciona la superficie de transferencia térmica necesaria.

- Tipos de flujo: Los fluidos se mueven de diferentes maneras para maximizar la transferencia.Flujo contracorriente es el diseño más eficiente. Los fluidos entran en el intercambiador desde extremos opuestos.

Qué hacemos

- Plato

- Hoja

- Piezas forjadas

- Barra redonda

- Brida

- Tuberías

- Accesorios

- Personalizado

Más información

Características

- Resistencia a la corrosión: La principal ventaja del acero inoxidable es su resistencia a la corrosión, ya que puede soportar productos químicos muy corrosivos. Calidades como el 316 y el dúplex resisten la erosión ácida.

- Alta resistencia mecánicaEste material resiste la deformación bajo alta presión, manteniendo la integridad estructural.

- Superficie higiénica: Su superficie lisa y no porosa facilita la limpieza, inhibe el crecimiento bacteriano y evita la adhesión de suciedad, lo que lo hace esencial para aplicaciones sanitarias.

- DurabilidadEl acero inoxidable presenta resistencia a la expansión térmica y a la fatiga, lo que garantiza una vida útil prolongada y reduce la necesidad de reemplazos frecuentes.

Ventajas

- Compatibilidad química: El acero inoxidable previene la corrosión química de las superficies metálicas.

- Larga vida útil: la capa de óxido pasivada protege el material contra la oxidación.

- Flexibilidad de diseño: El acero inoxidable se puede aplicar a diversas formas estructurales, incluidos los intercambiadores de calor de carcasa y tubos o de placas.

- Resistencia a altas temperaturas: La mayoría de los tipos de acero inoxidable conservan su resistencia en entornos con altas temperaturas.

Desventajas

- Conductividad térmica: el acero inoxidable conduce el calor más lentamente que otros metales.

- Mayor coste inicial: Los equipos de acero inoxidable tienen un coste inicial más elevado que los de acero al carbono.

- Sensibilidad a la soldadura: Algunos aceros inoxidables son sensibles al calor de soldadura, lo que puede requerir un tratamiento posterior adecuado.

- Tendencia a la formación de incrustaciones: El acero inoxidable puede acumular incrustaciones de agua, lo que requiere una limpieza y mantenimiento periódicos.

Grados comunes de intercambiadores de calor de acero inoxidable

Esta tabla detalla los grados comunes de acero inoxidable utilizados para tubo del intercambiador de calor. La elección del material depende de la corrosividad del fluido.

| Calificación | Característica principal | Lo mejor para |

|---|---|---|

| Acero 304 Acero 304L | Uso general | HVAC, baja presión |

| Acero 316 Acero 316L | Resistencia a los cloruros | Química, procesamiento de alimentos |

| Dúplex 2205 | Alta resistencia | Petróleo y gas, alta presión |

| Acero 904L | Excelente resistencia a los ácidos | Aplicaciones del ácido sulfúrico |

Tipos de intercambiadores de calor de acero inoxidable

| Escribe | Enfoque en el diseño | Aplicación clave |

|---|---|---|

| Carcasa y tubo | Alta presión | Centrales eléctricas, refinerías |

| Plato | Alta eficiencia | Alimentos, bebidas, climatización |

| Espiral | Fluidos viscosos | Procesamiento de lodos |

Aplicaciones de los intercambiadores de calor de acero inoxidable

- Alimentos y bebidas: Los intercambiadores se utilizan para la pasteurización y la refrigeración. La higiene es imprescindible en este sector. La superficie lisa de acero inoxidable evita la contaminación.

- Procesamiento químico: Las unidades resisten ácidos y productos químicos altamente corrosivos. Tubo enrollado del intercambiador de calor El diseño se utiliza a menudo. Maximiza la superficie en un espacio reducido.

- Industria farmacéutica: Los sistemas de alta pureza dependen de un control preciso de la temperatura. El acero inoxidable garantiza que no se produzca contaminación. Cumple con estrictos requisitos normativos.

- Generación de energía: Se utilizan en condensadores y sistemas de recuperación de calor. Los sistemas de intercambiadores de calor de acero inoxidable soportan altas presiones y altas temperaturas. Son fundamentales para la eficiencia del sistema.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/