¿Se empaña el acero inoxidable?Esta es una pregunta fundamental para cualquiera que compre tubos de acero inoxidable y accesorios de tubería de acero inoxidableLa respuesta es sencilla: el acero inoxidable de alta calidad resiste muy bien el deslustre, pero no es completamente inmune.

La ciencia de la resistencia del acero inoxidable

The protective mechanism of stainless steel lies in its passive protective layer.This thin film,composed of chromium oxide,forms instantly when the metal comes into contact with oxygen,shielding the underlying iron from corrosion and oxidation.Even if scratched or damaged,this film can rapidly self-repair as long as oxygen is present.

Qué hacemos

- Plato

- Hoja

- Piezas forjadas

- Barra redonda

- Brida

- Tuberías

- Accesorios

- Personalizado

Más información

Factores que provocan el deslustre y la decoloración

Saltwater and de-icing salts are major threats.Chloride ions are small and corrosive.They attack and penetrate the passive film.This causes pitting corrosion,which appears as tarnish or rust.

Evite el uso de lejía, amoniaco o productos de limpieza muy ácidos.

La abrasión física daña la película de pasivación, dejando al descubierto el hierro subyacente y provocando oxidación.

High heat from pipe welding can sensitize the steel.This causes chromium to migrate away from grain boundaries.The chromium-depleted area is left highly vulnerable to corrosion.

Ventajas clave de la resistencia del acero inoxidable al deslustre

Al entrar en contacto con el oxígeno, la película protectora se reconstruye inmediatamente.

Este material mantiene su lustrosa superficie durante décadas. Cuando se utiliza en entornos de leves a moderadamente duros, sus cualidades estéticas permanecen frescas y nuevas sin necesidad de pintura.

Different grades of materials perfectly suit different environments.316 stainless steel is a good choice for marine applications,while other grades meet requirements for high purity or high temperatures.

La superficie no porosa facilita la limpieza y evita eficazmente la acumulación de suciedad y bacterias.Adecuado para sistemas de tuberías sanitarias.

Posibles causas del deslustre del acero inoxidable

304 stainless steel is prone to pitting corrosion in high-chloride environments.This localized corrosion manifests as dark spots or discoloration.Molybdenum-containing grades, such as 316 stainless steel, must be used.

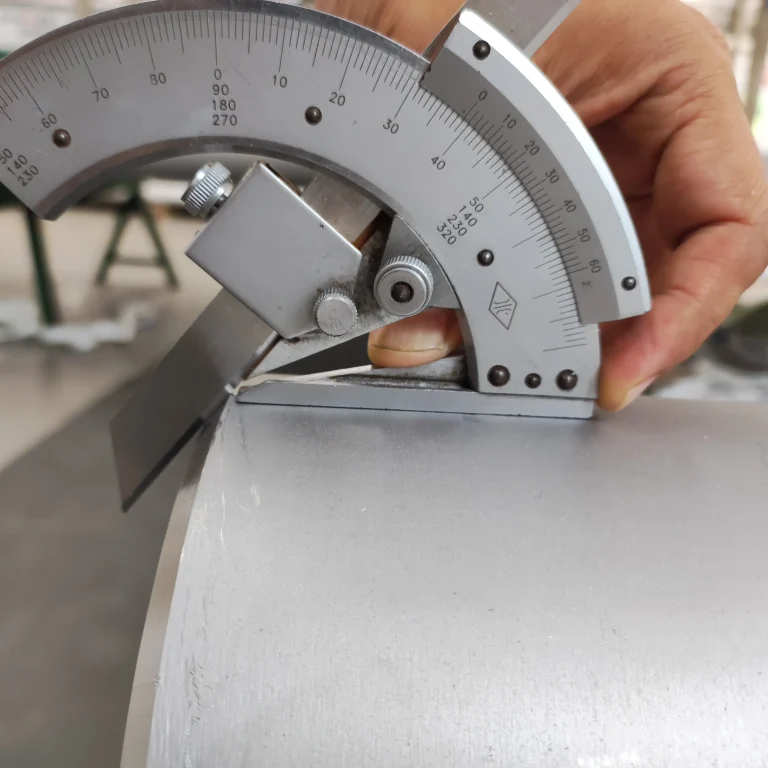

High temperatures during manufacturing may cause discoloration,appearing as blue or yellow tints on the surface.This heat discoloration must be eliminated through post-weld heat treatment to restore the material’s full corrosion resistance.

Contamination and corrosion may lurk in narrow crevices.This is called crevice corrosion.Such conditions often occur beneath gaskets or fasteners. Proper joint design can minimize these vulnerable areas.

En presencia de humedad, pueden producirse reacciones electroquímicas que aceleren el deterioro de uno de los metales.

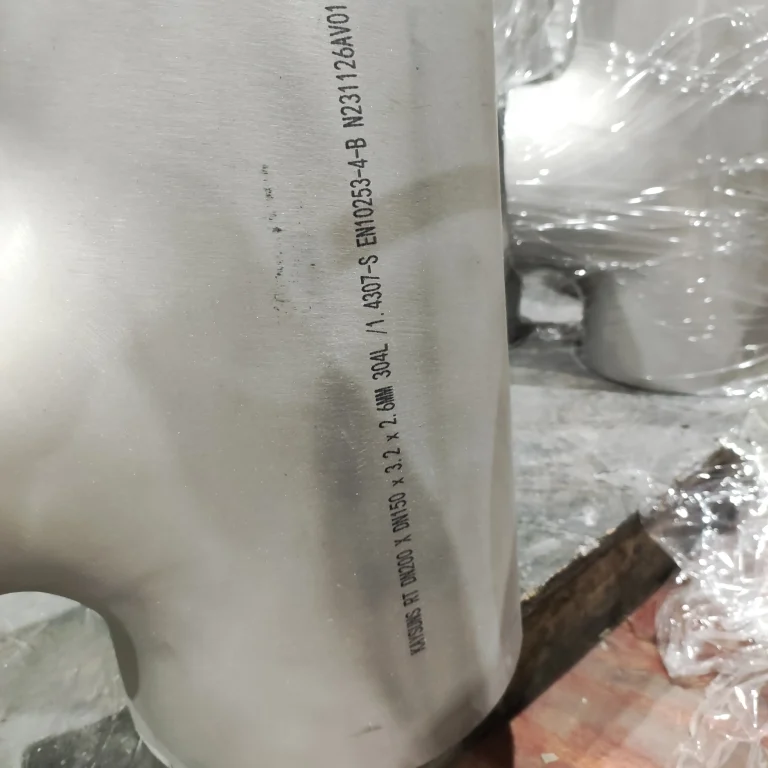

Composición química

| Calificación | Cr | Ni | Mes | Resistencia al deslustre |

|---|---|---|---|---|

| 304 | 18.0 – 20.0% | 8.0 – 10.5% | – | Bien |

| 316 | 16.0 – 18.0% | 10.0 – 14.0% | 2.0 – 3.0% | Excelente |

| Dúplex 2205 | 21.0 – 23.0% | 4.5 – 6.5% | 2.5 – 3.5% | Superior |

Calidades comunes de tubos Propiedades mecánicas

| Propiedad | Grado 304 | Grado 316 | Grado 2205 |

|---|---|---|---|

| Resistencia a la tracción (mín.) | ≥ 515 MPa | ≥ 515 MPa | ≥ 620 MPa |

| Límite elástico (mín.) | ≥ 205 MPa | ≥ 205 MPa | ≥ 450 MPa |

| Dureza (típica) | ≤ 92 HRB | ≤ 95 HRB | ≤ 293 HRB |

Prevención del deslustre en tuberías y accesorios

- Seleccionar el grado correcto: Elija el grado en función del entorno de la aplicación. Cuando esté expuesto a la sal o al cloruro, utilice siempre grados de acero inoxidable 316 o dúplex. El mayor coste asociado a un mayor contenido de molibdeno está justificado.

- Limpieza y pasivación: Los materiales deben limpiarse después de la soldadura o el mecanizado. El tratamiento térmico posterior a la soldadura elimina la decoloración por calor y la ferrita superficial. La pasivación restaura la capa protectora de óxido de cromo.

- Evitar la contaminación por hierro: Prohibir terminantemente el contacto del acero inoxidable con el acero al carbono. Las partículas de hierro se transferirán a la superficie, donde son muy susceptibles a la oxidación.

- Mantenimiento rutinario: Limpie regularmente los accesorios de tubería de acero inoxidable. Utilice agua jabonosa suave para eliminar la suciedad y los depósitos de sal, asegurándose de secar bien las superficies después de la limpieza.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/