Hastelloy G es una familia de aleaciones de níquel, cromo, hierro y molibdeno que ofrece una excelente resistencia a la corrosión en una amplia gama de entornos químicos. tubos de acero inoxidable o accesorios de tubería de acero inoxidable fracasaría.

Introducción a la serie Hastelloy G

La serie Hastelloy G es un grupo especializado de aleaciones cuyos elementos clave son el níquel, el cromo, el hierro y el molibdeno. Estas aleaciones funcionan bien tanto en ambientes oxidantes como reductores. También incluyen cobre, que mejora la resistencia a los ácidos sulfúrico y fosfórico.

Qué es la aleación Hastelloy

La aleación Hastelloy contiene una elevada proporción de níquel, además de cromo y molibdeno. La familia incluye tres series principales. Son la serie B, la serie C y la serie G. Cada una está diseñada para entornos específicos.

Qué hacemos

- Plato

- Hoja

- Piezas forjadas

- Barra redonda

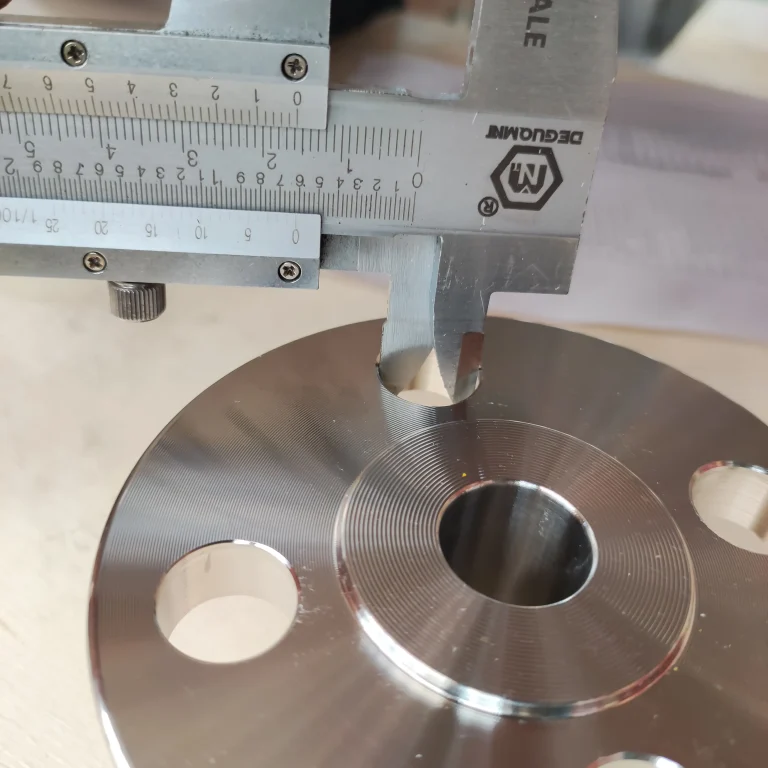

- Brida

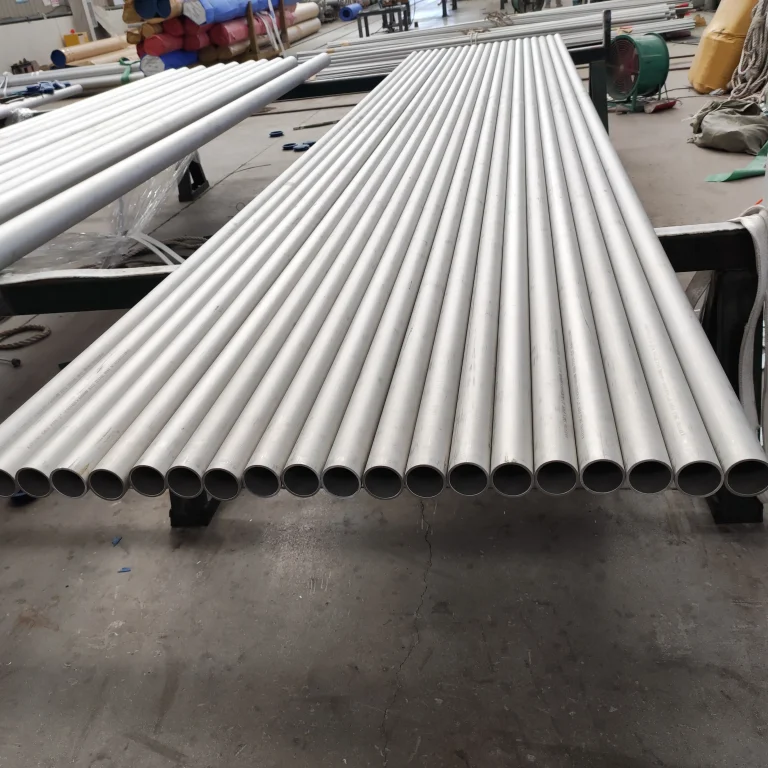

- Tuberías

- Accesorios

- Personalizado

Más información

Principales ventajas de la serie Hastelloy G

Esta aleación soporta bien una mezcla de ácidos. La resistencia a los medios oxidantes y reductores es una ventaja clave. Ofrece un rendimiento superior frente a los ácidos sulfúrico y fosfórico.

La composición de la aleación combate activamente la corrosión por picaduras y la corrosión por intersticios. Por este motivo, suele ser una opción mejor que muchos aceros inoxidables.

La facilidad de fabricación es una de las principales ventajas. Se forman soldaduras fuertes sin perder propiedades. Así, es más fácil fabricar tuberías y accesorios complejos.

Un bajo contenido en carbono evita la sensibilización tras la soldadura. Esto garantiza que la aleación conserve su resistencia a la corrosión. El material se comporta bien en la zona afectada por el calor.

Principales desventajas de la serie Hastelloy G

La composición contiene níquel y molibdeno, muy caros, cuya adición hace subir el precio.

Este material de aleación tiene una alta densidad, lo que aumenta el peso del sistema. Sus características de alta densidad deben tenerse en cuenta durante el diseño y la planificación de la estructura de soporte.

Una dureza elevada conlleva dificultades de mecanizado, que requieren herramientas y velocidades de mecanizado especializadas, lo que aumenta el tiempo y los costes de fabricación.

La aleación presenta una buena resistencia a las altas temperaturas. Sin embargo, no es una opción principal para aplicaciones de alta resistencia y alta temperatura. La aleación carece de las propiedades de otras superaleaciones para uso estructural a altas temperaturas.

El proceso de degradación natural del Hastelloy G

- Fluencia y fractura por tensión: Las altas temperaturas y la tensión sostenida pueden causar una deformación lenta y permanente conocida como fluencia. Con el tiempo, esto puede conducir finalmente al fallo. La resistencia de la aleación disminuye gradualmente con la exposición prolongada.

- Fatiga: Los ciclos de tensión repetidos pueden inducir microfisuras en los componentes. Estas grietas se propagan progresivamente y acaban provocando el fallo del componente.

- Corrosión a largo plazo: A pesar de la alta resistencia a la corrosión, la exposición prolongada a productos químicos altamente corrosivos puede degradar el material. Con el tiempo, puede producirse corrosión por picaduras o adelgazamiento de la superficie. Aunque extremadamente lento, este proceso es un fenómeno natural dentro del ciclo de vida de la aleación.

- Erosión-Corrosión: Los entornos que implican el flujo de fluidos a alta velocidad inducen una forma específica de degradación. Los efectos combinados de la erosión y la corrosión desgastan continuamente la aleación, acortando potencialmente su vida útil en determinadas aplicaciones.

Calidades comunes de Hastelloy G

| Calificación | Elementos clave | Ventaja principal |

|---|---|---|

| Hastelloy G3 | Cr/Fe/Mo | Fácil de soldar, resistente a las picaduras |

| Hastelloy G30 | Cr/Fe/Mo | Resistencia al ácido fosfórico |

| Hastelloy G35 | Cr/Fe/Mo | Alta resistencia, resiste el ataque del cloruro |

| Hastelloy G50 | Cr/Fe/Mo | Bueno para ácido sulfúrico a alta temperatura |

Hastelloy G VS Acero inoxidable

| Característica | Hastelloy G | Acero inoxidable |

|---|---|---|

| Ácidos mixtos | Excelente | Pobre |

| Corrosión por picaduras y grietas | Excelente | Bien |

| Resistencia a los cloruros | Excelente | Bien |

| Coste | Muy alta | Medio |

| Uso principal | Entornos de ácido fosfórico | Resistencia general a la corrosión |

Hastelloy Serie G en sistemas de tuberías

- Tratamiento químico: El Hastelloy G proporciona una resistencia extrema a la corrosión para los accesorios de tuberías críticos de acero inoxidable. Su sistema funciona perfectamente, incluso con mezclas ácidas agresivas.

- Producción de fertilizantes: La aleación es perfecta para manipular ácido fosfórico de proceso húmedo. Soporta productos químicos altamente corrosivos. Su uso garantiza un funcionamiento eficaz y seguro.

- Desulfuración de gases de combustión: Un uso clave de esta aleación. Resiste los entornos corrosivos de las centrales eléctricas. Su alta resistencia protege tuberías y accesorios.

- Tratamiento de residuos: El material es esencial para tuberías y accesorios en el tratamiento de residuos. El Hastelloy G soporta productos químicos corrosivos. La aleación mantiene su integridad. Esto evita fugas y costosos tiempos de inactividad.

Suministro y fabricación de aleaciones Hastelloy

Se requiere un informe completo del ensayo de materiales (MTR). Verifica la composición exacta de la aleación y garantiza su rendimiento.

Trabajar con proveedores especializados de tuberías y accesorios de acero inoxidable. Conocen estos aceros aleados y pueden garantizar una fabricación y un control de calidad adecuados, y cuentan con las certificaciones ISO 9001 y CE-PED.

Esta aleación requiere procedimientos específicos. Una técnica de soldadura adecuada garantiza la integridad de la soldadura.

Es caro, por lo que es importante evaluar si el producto tiene una vida útil más larga. Esto puede justificar su mayor coste inicial.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/