Qué es el óxido de brida

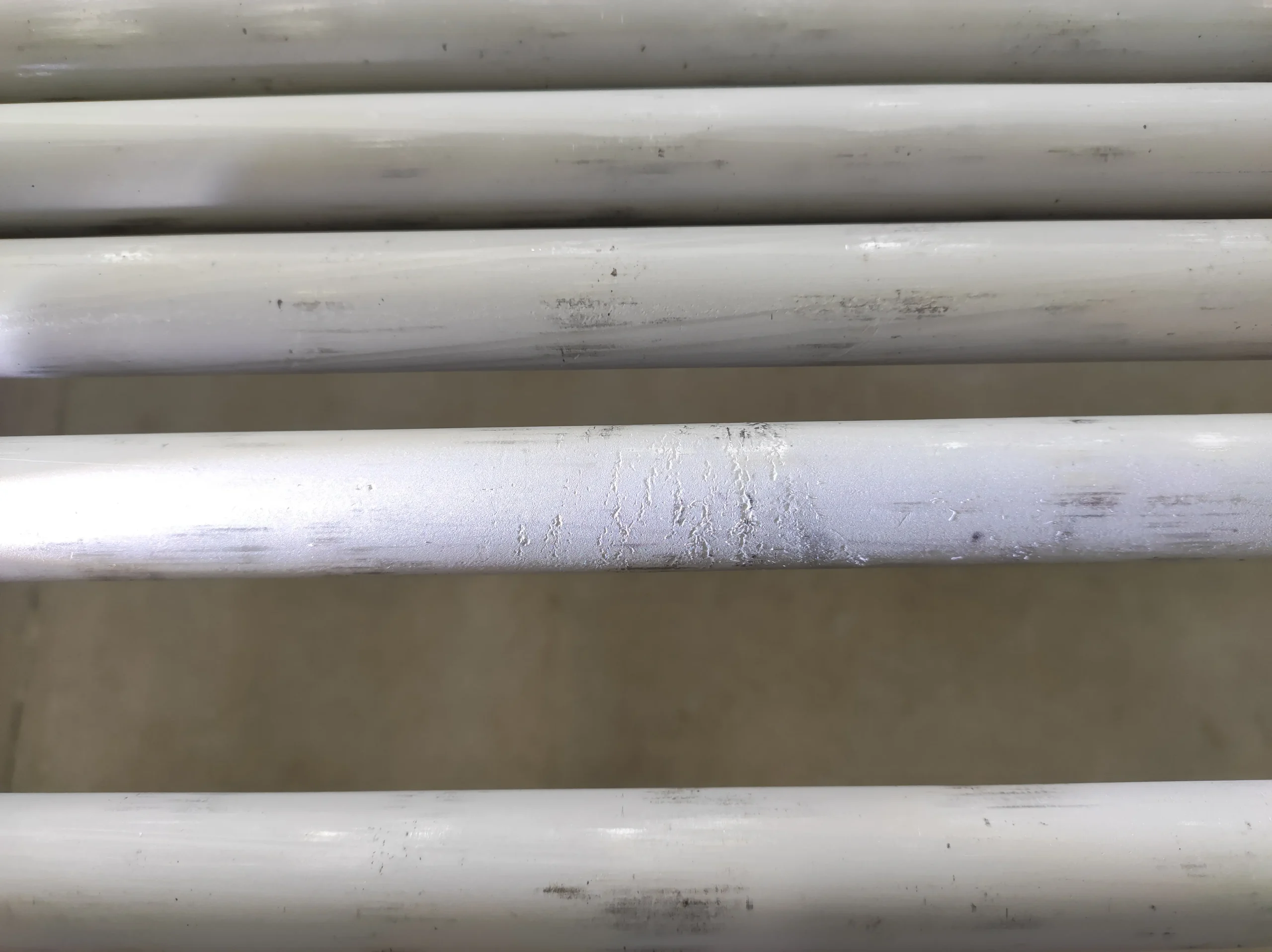

Óxido de la brida es un problema grave en muchos sistemas industriales. Afecta directamente a la seguridad y eficacia de las redes de tuberías. bridas de acero inoxidable Esto es válido para los sistemas que utilizan tubos de acero inoxidable y accesorios de tubería de acero inoxidableComprender por qué se produce la corrosión es el primer paso. La selección adecuada del material es clave para prevenir el fallo de las bridas.

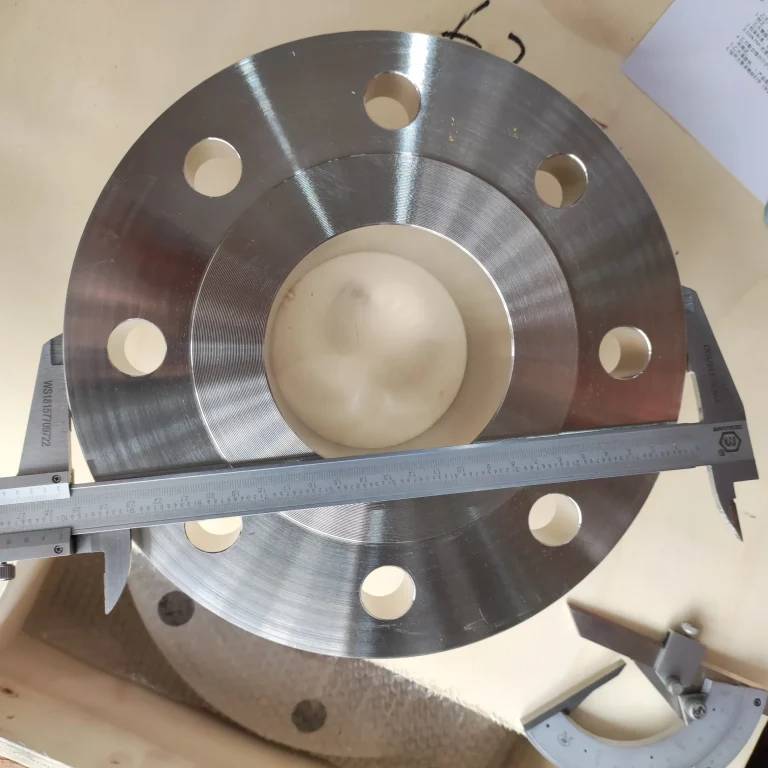

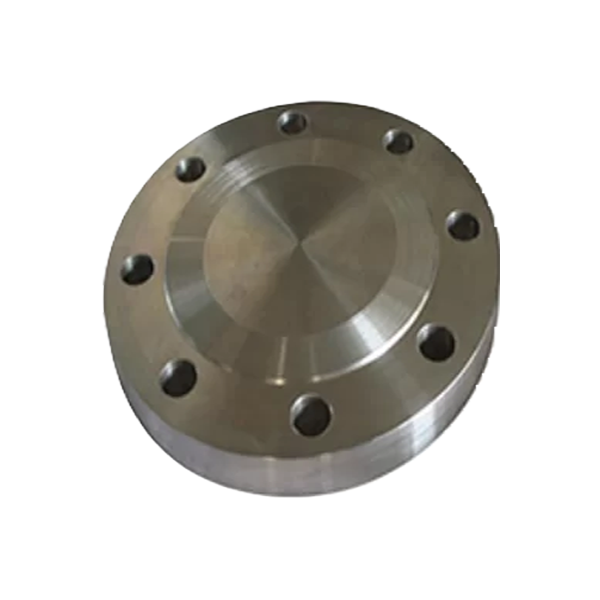

Qué es una brida

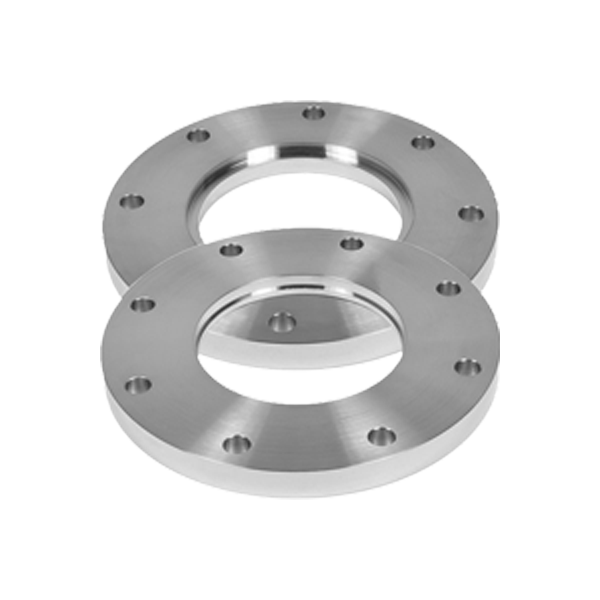

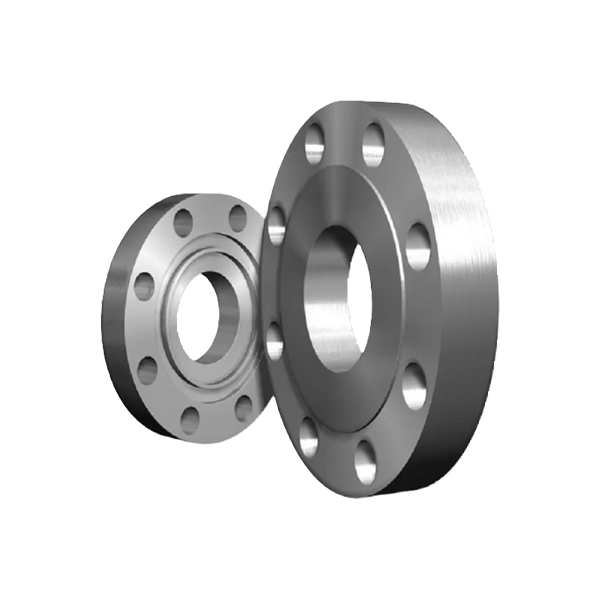

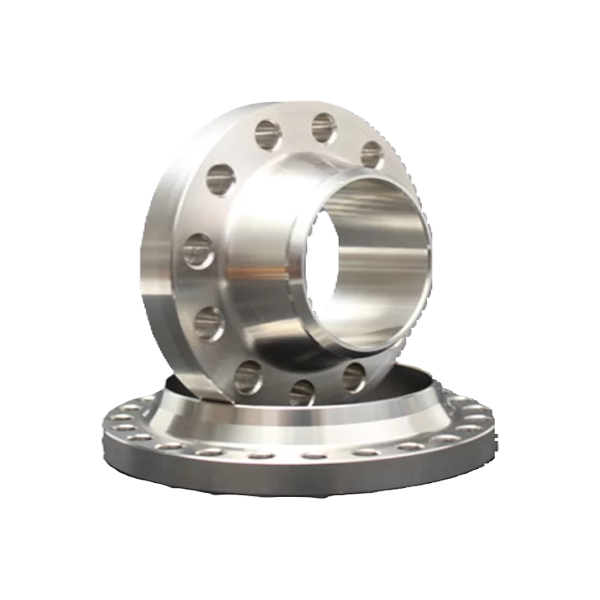

¿Qué es una brida? Las bridas son un tipo de conexión que se utiliza para unir tuberías,valvulasy otros equipos. Este método de conexión es seguro y fiable, a la vez que facilita el desmontaje.Bridas se fabrican con diversos materiales seleccionados por su solidez y resistencia a la corrosión.

Principales desventajas de la oxidación de bridas

La oxidación de las bridas puede provocar picaduras Esto reduce la capacidad de la brida para soportar la presión y puede provocar fallos repentinos. Una brida debilitada es un grave riesgo para la seguridad.

El óxido de las bridas degrada la superficie de sellado. Esto crea vías de fuga. Las fugas de fluidos de proceso pueden ser peligrosas. Provocan riesgos medioambientales y de seguridad. Esta contaminación también provoca la ineficacia del sistema.

Los efectos de la oxidación de las bridas obligan a inspeccionarlas con mayor frecuencia. Requieren reparaciones costosas o la sustitución completa. Esto se traduce en importantes tiempos de inactividad no planificados. Estos costes se acumulan con el tiempo.

En última instancia, la oxidación de las bridas acorta la vida útil de todo el sistema. Obliga a la sustitución prematura de componentes. Esta corrosión puede extenderse a las tuberías de conexión. Todo el sistema puede necesitar una revisión completa. Esto es mucho más caro.

Selección de materiales para combatir el óxido de las bridas

Composición química por material

| Material | Fe | Cr | Ni | Mes | Otros elementos |

|---|---|---|---|---|---|

| Acero 304 | Bal. | 18.0 – 20.0 | 8.0 – 10.5 | – | C: ≤0,08, Si: ≤1,0, Mn: ≤2,0 |

| Acero 316L | Bal. | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | C: ≤0,03, Si: ≤1,0, Mn: ≤2,0 |

| Titanio | Bal. | – | – | – | Ti: ≥99.2, N: ≤0.03, H: ≤0.015, Fe: ≤0.3, O: ≤0.25 |

| Aluminio | 0 - 0.7 | 0.04 – 0.35 | – | – | Al: Bal., Mg: 0,8-1,2, Si: 0,4-0,8, Cu: 0.15-0.4 |

Propiedades mecánicas por material

| Propiedad | Acero 304 | Acero 316L | Titanio | Aluminio |

|---|---|---|---|---|

| Resistencia a la tracción (MPa) | ≥515 | ≥485 | ≥345 | ≥275 |

| Límite elástico (0.2% Offset) (MPa) | ≥205 | ≥170 | ≥275 | ≥240 |

| Alargamiento (%) | ≥40 | ≥40 | ≥20 | ≥10 |

Aplicaciones de bridas en sistemas de tuberías

Las bridas de estos sistemas se enfrentan a ácidos y productos químicos altamente corrosivos.Acero inoxidable 316L es una opción popular. contenido de molibdeno Se utiliza a menudo para accesorios de tuberías de acero inoxidable en plantas químicas.

Estos ambientes tienen un alto contenido de cloruro.El agua de mar es muy corrosiva.Por lo tanto, brida de titanio Ofrecen una mayor resistencia a las picaduras y a la corrosión. corrosión en grietasEsto garantiza la fiabilidad del sistema y una larga vida útil.

los Brida en petróleo y gas La industria petrolera opera bajo presiones y temperaturas extremas. Las bridas deben resistir los hidrocarburos corrosivos y las duras condiciones del fondo del pozo. Las aleaciones de alta calidad son esenciales para evitar la oxidación de las bridas y los fallos catastróficos.

Para entornos menos agresivos,Acero inoxidable 304 Ofrecen un gran equilibrio entre coste y resistencia a la corrosión y son adecuadas para muchas aplicaciones de tuberías de acero inoxidable.

A brida de aluminio Se eligen por su ligereza y su resistencia moderada y son adecuados para aplicaciones de baja presión.

Cómo prevenir la oxidación de las bridas

- Elija el material adecuado:Este es el paso más importante.Seleccione un material de brida resistente a su entorno de funcionamiento específico.Por ejemplo, utilice acero inoxidable 316L para evitar la oxidación de la brida en condiciones marinas.Para productos químicos extremadamente agresivos, el titanio es una mejor opción.

- Solicitar Revestimientos protectoresLos revestimientos crean una barrera que separa el material de la brida de los elementos corrosivos. Se pueden aplicar revestimientos ricos en zinc, pinturas o envolturas anticorrosión especializadas, lo que constituye una forma eficaz de detener la oxidación de las bridas de acero al carbono.

- Poner en marcha un Calendario de mantenimientoLas inspecciones periódicas son cruciales para detectar signos tempranos de óxido en las bridas, como picaduras o decoloración, y solucionarlos de inmediato mediante su limpieza o reparación. De este modo se detiene la propagación del óxido en las bridas y se prolonga su vida útil.

- Asegúrese de que la instalación es correcta:Es esencial que la conexión de la brida sea estanca y esté bien instalada. junta de brida Un sellado deficiente permite la entrada de humedad y fluidos corrosivos, lo que puede provocar la oxidación de la brida en la superficie de sellado.

- Controle el entorno: Siempre que sea posible, controle el entorno de las bridas: utilice deshumidificadores en zonas de alta humedad. El aislamiento también puede evitar la formación de condensación en las superficies de las bridas.

Bridas que ofrecemos

Puede que también quiera leer:

Ligero o poderoso. Brida de aluminio frente a brida de titanio. ¿Cuál gana para su proyecto?

¿Cómo elegir una brida?

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/