Aleación Hastelloy es una familia de superaleaciones. Proporciona una solución fiable para necesidades extremas. Estándar tubos de acero inoxidable y accesorios de tubería de acero inoxidable a menudo carece de la resistencia necesaria. También tiene problemas con la corrosión. Aquí es donde la aleación Hastelloy ofrece una solución superior.

Aleación Hastelloy: un campeón resistente a la corrosión

La aleación Hastelloy es una superaleación a base de níquel. Contiene una elevada proporción de níquel, así como cromo y molibdeno. Estos elementos le confieren una excelente resistencia a la corrosión. Esto es especialmente cierto en medios agresivos. La familia incluye tres series principales. Son las series B, C y G. Cada una está diseñada para entornos específicos.

Qué hacemos

- Tuberías >

- Accesorios >

- Bridas >

- Más >

Principales ventajas de la aleación Hastelloy

La aleación Hastelloy proporciona una gran resistencia. Combate los ácidos fuertes y resiste los cáusticos.

Mantiene su resistencia , funciona con fiabilidad a temperaturas elevadas , resiste el reblandecimiento bajo el calor.

Esta aleación es fácil de conformar. Se puede soldar fácilmente y garantiza uniones fuertes y fiables para los sistemas de tuberías.

Esta aleación es muy versátil. Se utiliza en procesos químicos y en electrónica.

Diferencias clave : Serie B,C,G

| Serie | Elemento principal | Característica principal | Aplicación común |

|---|---|---|---|

| Hastelloy B | Molibdeno | Excelente resistencia a los ácidos reductores | Ácido clorhídrico, ácido sulfúrico |

| Hastelloy C | Cromo y molibdeno | Resistencia total (buey y rojo) | Cloro húmedo, ácidos mixtos |

| Hastelloy G | Cromo, hierro y molibdeno | Resistencia al ácido fosfórico, sulfúrico | Producción de abono ácido |

Aleación Hastelloy Serie C

| Calificación | Elementos clave | Ventaja principal |

|---|---|---|

| Hastelloy C4 | Cr/Mo/Ti | Thermal stability, resists IGC |

| Hastelloy C22 | Cr/Mo/W | Resistencia universal (ox. y rojo) |

| Hastelloy C59 | Cr/Mo | Very high pitting resistance |

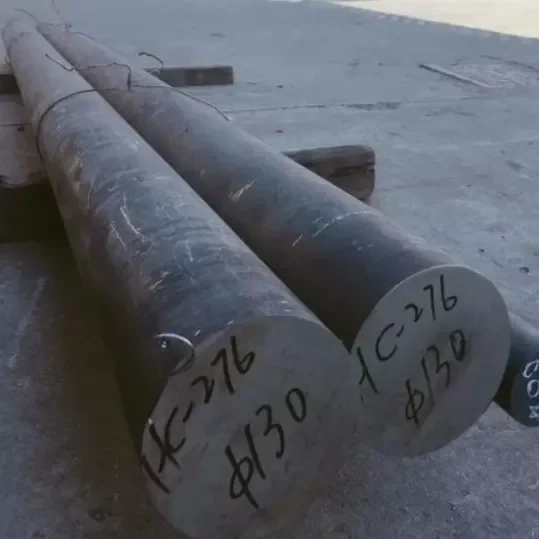

| Hastelloy C276 | Cr/Mo/W | Resistencia a la corrosión polivalente |

| Hastelloy C2000 | Cr/Mo/Cu | Universal (ox., red., ácido sulfúrico) |

Aleación Hastelloy Serie B

| Calificación | Elementos clave | Ventaja principal |

|---|---|---|

| Hastelloy B2 | Ni/Mo | Resistencia al ácido clorhídrico |

| Hastelloy B3 | Ni/Mo | Mayor estabilidad térmica |

| Hastelloy B4 | Ni/Mo | Buena estabilidad térmica |

Aleación Hastelloy Serie G

| Calificación | Elementos clave | Ventaja principal |

|---|---|---|

| Hastelloy G3 | Cr/Fe/Mo | Fácil de soldar, resistente a las picaduras |

| Hastelloy G30 | Cr/Fe/Mo | Resistencia al ácido fosfórico |

| Hastelloy G35 | Cr/Fe/Mo | Alta resistencia, resiste a los cloruros |

| Hastelloy G50 | Cr/Fe/Mo | Bueno para ácido sulfúrico a alta temperatura |

Aleación Hastelloy en sistemas de tuberías

- Tratamiento químico: El tratamiento con ácido fuerte proporciona resistencia al agrietamiento por corrosión bajo tensión, prolongando significativamente la vida útil del equipo.

- Control de la contaminación: Los sistemas de desulfuración de gases de combustión soportan condensados ácidos altamente corrosivos.

- Industria del petróleo y el gas: Adecuado para entornos de gas con contenido de azufre, resiste condiciones de funcionamiento duras.

- Aeroespacial: Los componentes del motor y los sistemas de escape soportan temperaturas y tensiones extremas.

- Sistemas de tuberías: Los accesorios críticos de acero inoxidable requieren una resistencia excepcional a la corrosión para garantizar la integridad del sistema.

Suministro y fabricación de aleaciones Hastelloy

A complete material test report (MTR) is required. It verifies the precise composition of the alloy and ensures its performance.

Work with specialized suppliers of tubería y accesorios de acero inoxidable. They understand these alloy steels and can ensure proper fabrication and quality control,and are ISO 9001 and CE-PED certified.

Esta aleación requiere procedimientos específicos. Una técnica de soldadura adecuada garantiza la integridad de la soldadura.

Es caro, por lo que es importante evaluar si el producto tiene una vida útil más larga. Esto puede justificar su mayor coste inicial.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/