Acero inoxidable frente a acero al carbono La elección de un material u otro es fundamental para el sistema de tuberías, ya que influye en el rendimiento, el coste y la vida útil. Comprender sus propiedades únicas es vital. tubería de acero inoxidable y el proveedor de accesorios le ayuda a decidir.

Acero inoxidable frente a acero al carbono: diferencia fundamental

La principal diferencia radica en el contenido de cromo: el acero inoxidable contiene un mínimo de 10,5% de cromo. Este elemento forma una fina capa pasiva. Esta capa evita la oxidación y la corrosión. El acero al carbono carece de este cromo. Es principalmente una aleación de hierro y carbono, por lo que se oxida fácilmente cuando se expone a la humedad. Esta diferencia clave dicta sus aplicaciones.

Acero inoxidable frente a acero al carbono: ventajas y desventajas

El acero inoxidable presenta una resistencia superior a la corrosión. La capa de óxido de cromo lo protege. El acero al carbono se oxida rápidamente sin una capa protectora. Esto hace que el acero inoxidable sea ideal para entornos húmedos o corrosivos.

El acero al carbono suele ser más asequible. Ofrece una buena resistencia. El acero inoxidable es más caro. Esto se debe a su contenido en cromo y níquel. Para muchas aplicaciones estructurales, el acero al carbono es una opción rentable.

El acero inoxidable requiere menos mantenimiento. Su resistencia a la corrosión se traduce en una vida útil más larga. El acero al carbono necesita revestimientos protectores. Estos revestimientos deben volver a aplicarse. Esto aumenta los costes de mantenimiento a largo plazo.

Ambos son soldables. El acero al carbono suele ser más fácil de soldar. El acero inoxidable requiere técnicas específicas. Esto se debe a sus elementos de aleación. Esto puede afectar a los costes y la velocidad de fabricación.

Acero inoxidable frente a acero al carbono: propiedades clave

| Característica | Acero inoxidable | Acero carbono |

|---|---|---|

| Resistencia a la corrosión | Excelente | Deficiente (sin recubrimiento) |

| Coste | Alta | Bajo |

| Fuerza | Bueno a muy alto | Muy alta |

| Soldabilidad | Bueno (con cuidado especial) | Excelente |

| Apariencia | Brillante, limpio, estético. | Opaco, requiere recubrimiento |

Qué hacemos

- Tuberías >

- Accesorios >

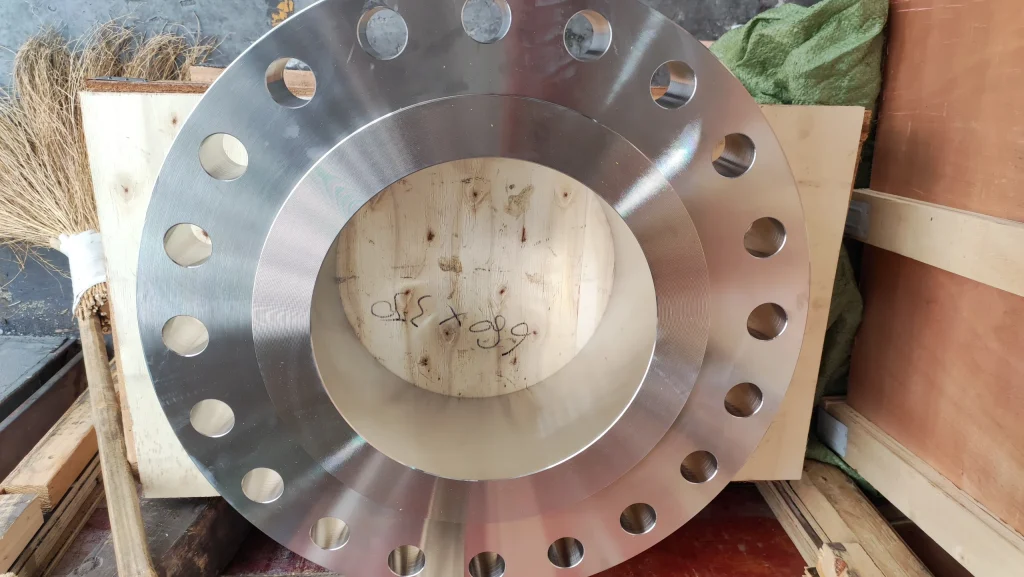

- Bridas >

- Más >

Acero inoxidable frente a acero al carbono: aplicaciones

| Tipo de aplicación | Acero inoxidable preferido | Acero al carbono preferido |

|---|---|---|

| Entornos corrosivos | Procesamiento químico, alimentación, marino | No recomendado (a menos que esté recubierto) |

| Utilidades generales | Agua de alta pureza, gas medicinal | Agua, aceite, gas (no corrosivo) |

| Estructural | Arquitectónico, decorativo, exterior | Edificios, maquinaria pesada, estructuras |

| Altas temperaturas | Hornos, intercambiadores de calor | Centrales eléctricas, tuberías de vapor |

| Proyectos sensibles al coste | Cuando la corrosión es un factor | Cuando el coste es el factor principal |

Calidades comunes del acero inoxidable

| Calificación | Característica principal | Ventaja principal | Caso de uso típico |

|---|---|---|---|

| 304/304L | Aleación estándar | Económico, buena resistencia a la oxidación. | Servicios generales, alimentación |

| 316/316L | Molibdeno añadido | Resistencia a los cloruros, sin picaduras | Marina, química, farmacéutica |

| 310S | Alto contenido de Cr/Ni | Excelente resistencia a altas temperaturas | Piezas de hornos, intercambiadores |

| 2205 (Dúplex) | Ferrítico-austenítico | Alta resistencia, resistente al SCC | Servicio offshore, ácido |

| 321 | Estabilizado con titanio | Resiste la degradación de la soldadura. | Escape de alta temperatura |

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/