Corrosión post-soldadura puede dañar seriamente su tubos de acero inoxidable y accesorios. Si tenemos que confiar en un sistema de tuberías robusto, debemos aprender todo lo que podamos sobre él. Siga leyendo para saber más sobre cómo evitar la corrosión postsoldadura siempre que sea posible.

¿Qué es la corrosión post-soldadura? Daños después de la soldadura

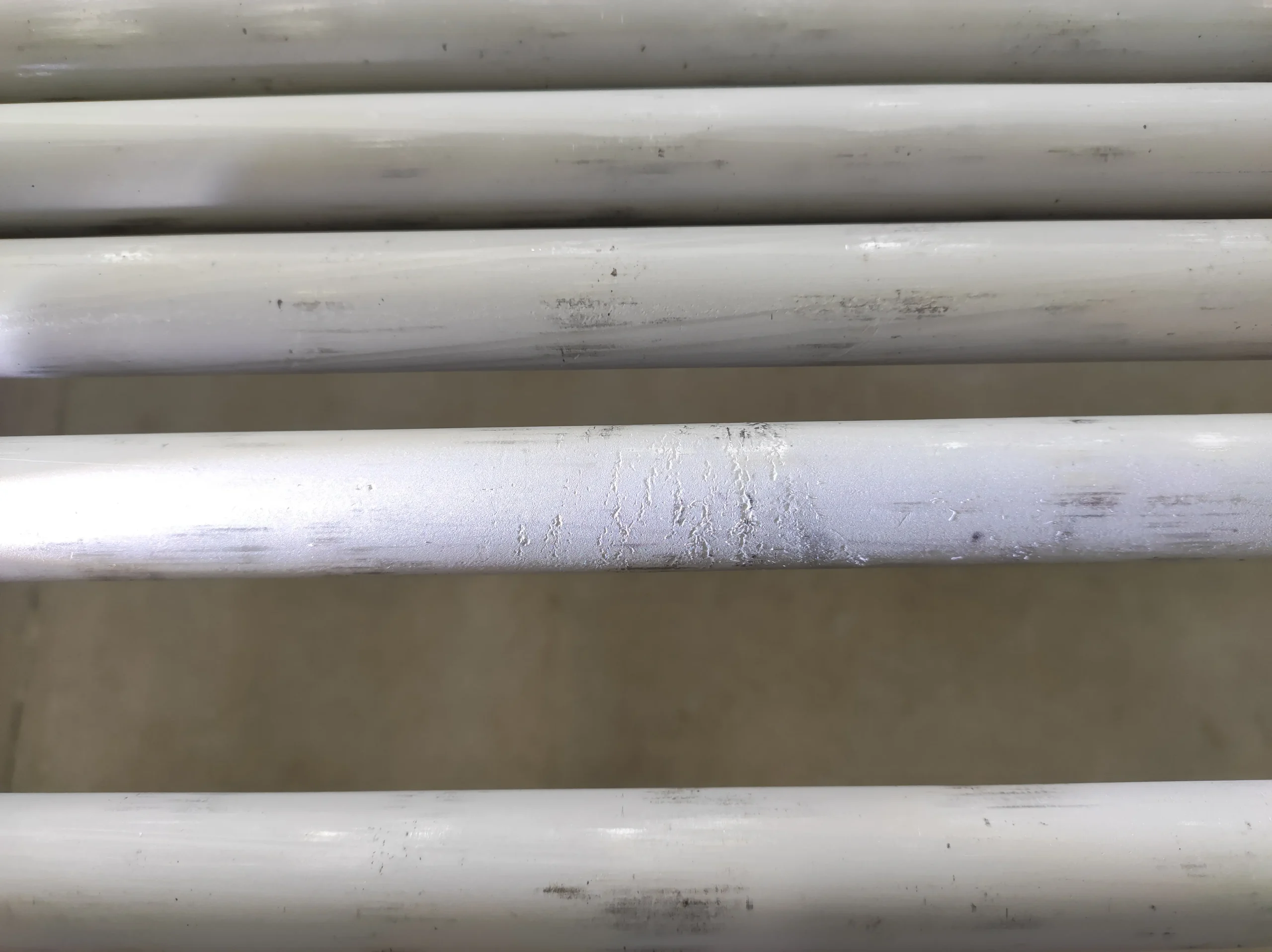

La corrosión posterior a la soldadura se produce en la unión soldada o cerca de ella. En proceso de soldadura cambia la microestructura del metal y estos cambios hacen que la zona sea más susceptible a la erosión. Puede aparecer inmediatamente y a veces se desarrolla con el tiempo. Debilita el componente y puede provocar averías muy graves.

Tipos comunes de corrosión posterior a la soldadura

Para comprender la corrosión postsoldadura es necesario reconocer sus distintas formas. Cada tipo tiene una causa y un aspecto específicos.

Corrosión intergranular se produce cuando cromo se agota cerca de los límites de grano. El calor de la soldadura puede provocar esta sensibilización. El ambiente corrosivo erosiona estas zonas débiles. Suele encontrarse junto al cordón de soldadura.

Corrosión por picadura crea pequeños agujeros localizados o picaduras. La soldadura puede provocar irregularidades en la superficie y también inclusiones de óxido.

Corrosión en grietas se produce en grietas estrechas. Estas grietas pueden estar situadas bajo la cascarilla o la escoria. Los defectos de soldadura también pueden crear grietas en las que los fluidos estancados pueden concentrar agentes corrosivos.

Agrietamiento por corrosión bajo tensión (SCC) es una combinación de tensión de tracción y un entorno corrosivo. La soldadura suele producir tensiones residuales. Cuando se expone a agentes corrosivos específicos, como los cloruros, se forman grietas. Pueden expandirse rápidamente, provocando un fallo repentino.

Los metales diferentes pueden unirse durante el proceso de soldadura, lo que se denomina corrosión galvánica. Esto también puede deberse a una elección inadecuada del metal de aportación, cuando se crea una diferencia de potencial que puede acelerar la corrosión del metal inerte.

Factores clave que contribuyen a la corrosión post-soldadura

| Factor | Descripción | Impacto en el acero inoxidable |

|---|---|---|

| Entrada de calor (soldadura) | Calor excesivo o insuficiente | Sensibilizacióncambios microestructurales |

| Sensibilización del material | Agotamiento del cromo debido al calor | Corrosión intergranular riesgo |

| Contaminación | Suciedad, grasa, escoria, salpicaduras, tinte térmico | Inicia la corrosión por picaduras y grietas. |

| Elección del metal de relleno | Incompatible con el metal base | Corrosión galvánicafragilización |

| Tensión residual | Tensiones restantes tras la soldadura | Aumenta la susceptibilidad al CCE |

| Entorno corrosivo | Presencia de productos químicos agresivos | Acelera todos los tipos de corrosión |

| Pasivación incorrecta | Falta de restauración de la capa pasiva | Reduces inherent resistencia a la corrosión |

Qué hacemos

Estrategias de prevención para soldaduras de acero inoxidable

| Estrategia | Descripción | Ventajas para las tuberías |

|---|---|---|

| Grados bajos en carbono | Utilice 304L, 316L (Grados L) | Minimiza carburo formación |

| Grados estabilizados | Utilice 321, 347, 316Ti | Previene el agotamiento del Cr |

| Entrada de calor controlada | Optimizar los parámetros de soldadura | Reduce la sensibilización |

| Post-soldadura Tratamiento térmico (PWHT) | Recocido después de la soldadura | Restaura las propiedades |

| Limpieza y pasivación adecuadas | Eliminar contaminantes, restaurar la capa | Aumenta la resistencia |

| Metal de relleno adecuado | Compatible con metal común | Evita el ataque galvánico |

| Acabado superficial Controlar | Evitar soldaduras rugosas, defectos | Minimiza los ataques localizados |

Impacto de la corrosión postsoldadura en tuberías y accesorios de acero inoxidable

- Fallos prematuros: Las soldaduras corroídas pueden provocar fugas que pueden causar roturas catastróficas.

- Reducción de la vida útil: Los equipos se deterioran más rápidamente, acortando su vida útil y aumentando la frecuencia de sustitución.

- Peligros para la seguridad: Las fugas de fluidos peligrosos son peligrosas, ya que suponen un riesgo para el personal y dañan el medio ambiente.

- Aumento de los costes de mantenimiento: Los costes de reparación, los costes de mano de obra y el aumento de los costes de tiempo incrementan significativamente los costes de explotación.

- Daños a la reputación: Los fallos del producto pueden dañar la confianza, afectando a la posición de su empresa y posiblemente a futuros contratos.

Contacto

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 577 8551 1171

- [email protected]

- https://www.kaysuns.com/