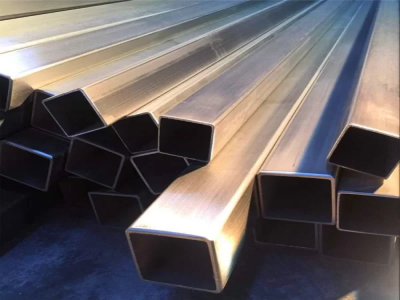

Duplex Pipe and Super Duplex 2507 Tubing

SAF 2205 Duplex pipe and SAF 2507 Super duplex pipe are our strength product. Duplex stainless steel (DSS) is an austenite-ferrite dual phase stainless steel, it is developed for applications that demand high strength and corrosion resistance. Duplex stainless steel pipe is a cost effective solution for many applications where the 300 series stainless steel pipe are susceptible to chloride stress corrosion cracking. 2205 Duplex pipe and 2507 super duplex stainless steel pipe is an idea choice for the applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. As a professional duplex pipe supplier in China, we provides high quality duplex 2205 (S31803) pipes and super duplex 2507 (S32750) pipe and tubing according to ASTM A790, ASTM A789, EN 10216-5 etc.

What is Duplex Stainless Steel Pipe:

Duplex Stainless Steel (DSS) including grades duplex 2205(S31803) and super duplex, they are commonly consist of 50% ferrite and 50% austenite, and generally requires not less than 30%. Duplex stainless steel has good welding performance and high strength. Compared with austenitic stainless steel, it is about double yield strength of stainless steel 316, 317 etc., it make the equipment lighter and stronger. Duplex stainless steel pipe has very good resistance to localized corrosion and stress corrosion cracking. Duplex steel is not intended to be used at temperatures above 300°C due to embrittlement, the continuous use temperature is from -50 to 250 °C.

Duplex and Super Duplex Grade:

Duplex Stainlss Steel SAF 2205(UNS S32205, S31803), Super duplex SAF 2507 (UNS S32750), S32760, S32304 etc.

SAF 2205 is the most common grade for duplex stainless steel, ASME/ASTM grade is UNS S32205 or the similar grade S31803 , equivalent to EN/DIN 1.4462.

SAF 2507 is a super duplex steel, the ASTM grade is S32750, equivalent to EN/DIN 1.4410. We can supply duplex pipes and fittings with high quality , mill cost and fast delivery time.

Duplex 2205 and super duplex 2507 is the common grade for us. For other grades, we can manufacturing and provide at considerable order quantity.

What is PREN for DSS and SDSS Pipe

What is PREN – Pitting Resistance Equivalent Number, abbreviated as PREN, is a set of algorithms calculated on the basis of the mass fraction of certain elements in the metal. The value is often used in the evaluation method for comparison of pitting corrosion resistance.

There is a formula for PREN calculating:

PREN=Cr%+3.3 *(Mo+0.5W)%+16 *N%

As per ASTM A790, PREN of 22 Cr duplex 2205 pipe is >31, and 25 Cr super duplex pipe is more than 40. If you have special requirement, you are welcome to contact us, our factory can accept customized fabrication.

What We Do for 2205 Duplex Pipe:

As professoinal duplex pipe supplier, our factory is mainly focus on the manufacturing of duplex stainless steel pipe, with good experience and reliable quality control system. Nowadays, Kaysuns supplies both duplex stainless steel pipe and super duplex stainless steel pipes and tubes conform to standard ASTM A790, ASTM A789, EN 10216-5 etc.

SAF 2507 Super duplex pipe is a super duplex steel pipe with 25% chromium, 4% molybdenum, and 7% nickel. The common grade of super duplex steel is SAF 5027 (S32750, S32760), they have similar composition and mechanical properties. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion. Compared to duplex stainless steel pipe, SAF 2507 super duplex pipe is highly resistant to uniform corrosion by organic acids such as formic and acetic acid.

molybdenum, and 7% nickel. The common grade of super duplex steel is SAF 5027 (S32750, S32760), they have similar composition and mechanical properties. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion. Compared to duplex stainless steel pipe, SAF 2507 super duplex pipe is highly resistant to uniform corrosion by organic acids such as formic and acetic acid.

*Super duplex S32760 is not a common grade in China, so we may couldn’t offer it with small quantity for pipes and butt-weld fittings. But it is available for forged fittings and flanges.

Manufacturing of DSS and SDSS Pipe

Cold drawn and cold rolled is the mainly process for seamless duplex stainless steel pipe. Due to the material characteristic of high strength and hardness, duplex steel is more difficult to process than austenitic steel. It is very easy to damage, especially for small thickness and large diameter pipes , it has a long and hard-working procedures, that’s why the delivery time of duplex pipe is long.

Duplex Pipe Specifications:

- ASTM SA789/SA789M -Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

- ASTM SA790/SA790M -Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

- ASTM SA928/SA928M -Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition of Filler Metal

- EN 10216-5 -Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 5: Stainless steel tubes

Our Capacity of Duplex Pipe:

- Product: Duplex Pipe and Super Duplex Pipe

- Seamless / Welded: We supply both seamless and welded pipe.

- Outer Diamater: 1/2″ to 24″ in seamless for pipes and 6mm to 420mm for tubings

- (Seamless is up to 24″, but welded can be 124″ if you like)

- Schedule: SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS

- Wall Thickness: 0.3mm to 12mm

- Manufucturing: Cold Finished

- Delivery Conditions: Solution Annealing

- Specifications: ASTM A789, ASTM A790, EN10216-5, EN/DIN17455-2, EN17456-2, GOST etc.

- Material Grade: UNS S31803, S32205, S32750, S32760, S32304, 1.4462, 1.4410, 1.4501, 1.4362 etc.

- Pipe End: Beveled End, Plain End (Generally we offer the pipes with plain ends for the size < 2″, and SCH10S )

To Be A Leading Duplex Pipe Supplier:

- Supply both seamless and welded.

- 15 years experience for fabrication and supplying.

- Heat treatment facility with computer temperature controlled .

- Reliable based material vendor management.

- Testing laboratory of NDT and PMI etc.

- Mill certificate to EN10204 3.1/3.2.

- Custom dimension fabricated and fast delivery time.

Where Is Duplex Stainless Used?

- Oil and gas industry equipment

- Chemical process industries

- Vessels and ship building

- Offshore platforms

- heat exchangers

- process and service water systems

- fire-fighting systems

- injection and ballast water systems

- Power industry FGD systems

- Utility and industrial scrubber systems, absorber towers, ducting, and piping

- Desalination plants, high pressure RO-plant and seawater piping

- Mechanical and structural components, high strength, corrosion-resistant parts

Duplex Stainless Steel Pipes Catalog

| Duplex Steel 2205 | |

| Super Duplex 2507 | |

| Stainless Steel Pipe Catalog | |

| Dimension of Duplex Stainless Steel Pipes | |

| ASTM SA789 -2010 | |

| ASTM SA790 -2010 |

*For more information about duplex pipe/super duplex pipe, please contact us.